inside diameter of a female fitting.

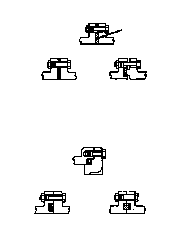

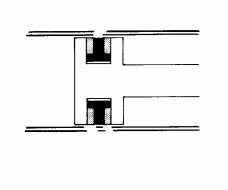

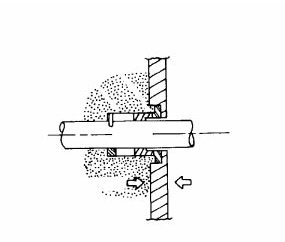

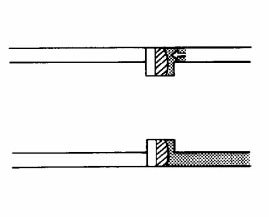

Figure 2-38 shows the assembly of a

clamp-type coupling. If you use this coupling,

do not skive the hose. Lubricate the ID of a

hose and the OD of a stem. Clamp a hose stem

in a bench vice and install a hose. Turn the

hose counterclockwise until it bottoms against

the shoulder of the stem (Figure 2-38, diagram

A). If you do not have a vice, force the stem

A

into the hose by pushing or striking the stem

with a wooden block. Place the clamp halves in

position (Figure 2-38, diagram B) and draw

them together with a vice or with extra long

bolts until the standard bolts protrude far

enough to grip the nuts. Remove the extra long

bolts and place retaining bolts through the

clamp. Tighten the nuts until you get the

required torque (Figure 2-38, diagram C).

NOTE: You may have to

retighten the bolts after the

hose assembly has been operat-

ing about 10 to 20 hours. Use

clamp-type couplings on hose

B

assemblies with diameters of 1

inch or greater. Use reusable

screw-type fittings on hose

assemblies with diameters less

than 1 inch.

2-11. Leakage. Any hydraulic system will

have a certain amount of leakage. Any leakage

will reduce efficiency and cause power loss.

Some leakage is built in (planned), some is not.

Leakage may be internal, external, or both.

a. Internal. This type of leakage (nonposi-

tive) must be built into hydraulic components

C

to lubricate valve spools, shafts, pistons, bear-

ings, pumping mechanisms, and other moving

parts. In some hydraulic valves and pump and

motor compensator controls, leakage paths are

Figure 2-38. Assembly of clamp-type

built in to provide precise control and to avoid

coupling

hunting (oscillation) of spools and pistons. Oil

is not lost in internal leakage; it returns to a reservoir through return lines or specially provided drain passages.

Too much internal leakage will slow down actuators. The power loss is accompanied by

the heat generated at a leakage path. In some instances, excess leakage in a valve could

cause a cylinder to drift or even creep when a valve is supposedly in neutral. In the case of Hydraulic Systems

2-29

FM 5-499

flow or pressure-control valves, leakage can often reduce effective control or even cause control to be lost.

Normal wear increases internal leakage, which provides larger flow paths for the leak-

ing oil. An oil that is low in viscosity leaks more readily than a heavy oil. Therefore an oil’s viscosity and viscosity index are important considerations in providing or preventing internal leakage. Internal leakage also increases with pressure, just as higher pressure causes a greater flow through an orifice. Operating above the recommended pressures adds the danger of excessive internal leakage and heat generation to other possible harmful effects.

A blown or ruptured internal seal can open a large enough leakage path to divert all of a

pump's delivery. When this happens, everything except the oil flow and heat generation at a

leakage point can stop.

b. External. External leakage can be hazardous, expensive, and unsightly. Faulty

installation and poor maintenance are the prime causes of external leakage. Joints may

leak because they were not put together properly or because shock and vibration in the lines

shook them loose. Adding supports to the lines prevents this. If assembled and installed

correctly, components seldom leak. However, failure to connect drain lines, excessive pres-

sures, or contamination can cause seals to blow or be damaged, resulting in external leakage

from the components.

c. Prevention. Proper installation, control of operating conditions, and proper maintenance help prevent leakage.

(1) Installation. Installing piping and tubing according to a manufacturer's recommen-

dations will promote long life of external seals. Vibration or stresses that result from

improper installation can shake loose connections and create puddles. Avoid pinching, cock-

ing, or incorrectly installing seals when assembling the units. Use any special tools that the manufacturer recommends for installing the seals.

(2) Operating Conditions. To ensure correct seal life, you must control the operating

conditions of the equipment. A shaft seal or piston-rod seal exposed to moisture, salt, dirt, or any other abrasive contaminate will have a shortened life span. Also, operators should

always try to keep their loads within the recommended limits to prevent leakage caused by

excessive pressures.

(3) Maintenance. Regular filter and oil changes, using a high-quality hydraulic oil, add

to seal life. Using inferior oil could wear on a seal and interfere with desirable oil properties.

Proper maintenance prevents impurity deposits and circulating ingredients that could wear

on a dynamic seal.

Never use additives without approval from the equipment and oil suppliers. Lubrica-

tion can be critical to a seal's life in dynamic applications. Synthetics do not absorb much oil and must be lubricated quickly or they will rub. Leather and fiber do absorb oil. Manufacturers recommend soaking a seal overnight in oil before installing it. Do not install a seal dry. Always coat it in clean hydraulic oil before installing it.

2-12. Seals. Seals are packing materials used to prevent leaks in liquid-powered systems.

A seal is any gasket, packing, seal ring, or other part designed specifically for sealing. Sealing applications are usually static or dynamic, depending if the parts being sealed move in

relation to one another. Sealing keeps the hydraulic oil flowing in passages to hold pressure and keep foreign materials from getting into the hydraulic passages. To prevent leakage,

2-30

Hydraulic Systems

FM 5-499

use a positive sealing method, which

involves using actual sealing parts or

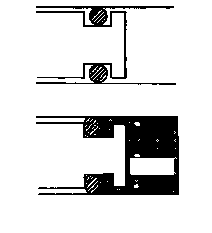

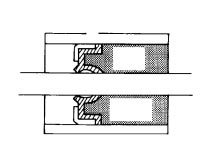

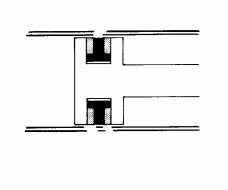

BASIC FLANGE JOINTS

materials. In most hydraulic compo-

nents, you can use nonpositive sealing

(leakage for lubrication) by fitting the

Gasket

parts closely together. The strength

of an oil film that the parts slide

Simple

against provides an effective seal.

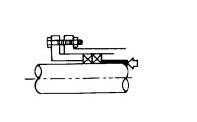

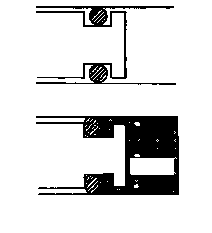

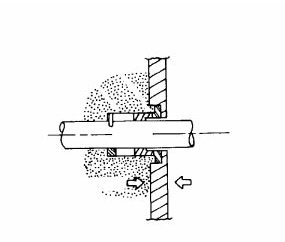

a. Static Seals. Pipe-threaded

Tongue-and groove

Tongue-and groove

seals, seal rings used with tube fit-

tings, valve end-cap seals, and other

seals on nonmoving parts are static

seals. Mounting gaskets and seals

METAL-TO-METAL JOINTS

are static, as are seals used in making

connections between components. A

static seal or gasket is placed between

parts that do not move in relation to

each other. Figure 2-39 shows some

typical static seals in flanged connec-

tions.

b. Dynamic Seals. In a dynamic

sealing application, either a recipro-

Figure 2-39. Static seals

cating or a rotary motion occurs between the two

parts being sealed; for example, a piston-to-bar-

rel seal in a hydraulic cylinder or a drive-shaft

seal in a pump or motor.

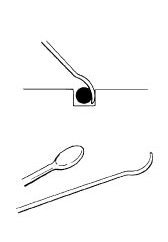

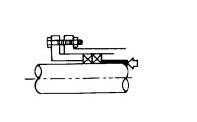

(1) O-Ring (Figure 2-40). An O-ring is a

positive seal that is used in static and dynamic

No

applications. It has replaced the flat gasket on

pressure

hydraulic equipment. When being installed,

an O-ring is squeezed at the top and bottom in

its groove and against the mating part. It is

capable of sealing very high pressure. Pressure

forces the seal against the side of its groove,

and the result is a positive seal on three sides.

Dynamic applications of an O-ring are usually

limited to reciprocating parts that have rela-

tively short motion.

Pressure

To remove an O-ring seal, you need a spe-

cial tool made of soft iron or aluminum or a

brass rod (Figure 2-41, page 2-32). Make sure

that the tool’s edges are flat and that you polish

any burrs and rough surfaces.

(2) Backup Ring (Figure 2-42, page 2-32).

Usually, made of stiff nylon, you can use a

Figure 2-40. O-ring placement

backup ring with an O-ring so that it is not

Hydraulic Systems

2-31

FM 5-499

forced into the space between the mating

parts. A combination of high pressure and

Surface must be smooth and

free from scratches.

clearance between the parts could call for a

backup ring.

Corners must not be dented

or bumped.

(3) Lathe-Cut Seal. This seal is like an O-

0.005 radius desired.

ring but is square in cross-section rather than

round. A lathe-cut ring is cut from extruded

tubes, while an O-ring must be individually

molded. In many static applications, round-

and square-section seals are interchangeable, if

made from the same material.

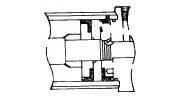

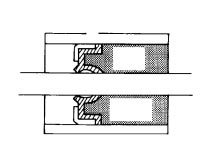

(4) T-Ring Seal (Figure 2-43). This seal is

reinforced with back-up rings on each side. A T-

ring seal is used in reciprocating dynamic appli-

cations, particularly on cylinder pistons and

around piston rods.

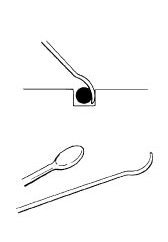

(5) Lip Seal (Figure 2-44). This a dynamic

Flatten as shown and polish

seal used mainly on rotating shafts. A sealing

off burrs and edges.

lip provides a positive seal against low pres-

sure. A lip is installed toward the pressure

source. Pressure against a lip balloons it out to

aid in sealing. Very high pressure, however,

can get past this kind of seal because it does not

Figure 2-41. O-ring removal tool

have the backup support that an O-ring has.

Sometimes, double-lip seals are

used on the shafts of reversible pumps

or motors. Reversing a unit can give

O ring

an alternating pressure and vacuum

condition in the chamber adjacent to a

seal. A double-lip seal, therefore, pre-

Pressure

vents oil from getting out or air and

dirt from getting in.

(6) Cup Seal (Figure 2-45). This is

a positive seal that is used on hydraulic

cylinder pistons and seals much like a

lip seal. A cup seal is backed up so that

it can handle very high pressures.

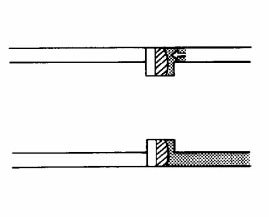

(7) Piston Ring (Figure 2-46). A

piston ring is used to seal pressure at

Back-up ring

the end of a reciprocating piston. It

helps keep friction at a minimum in a

hydraulic cylinder and offers less resis-

tance to movement than a cup seal. A

piston ring is used in many complex

components and systems to seal fluid

Figure 2-42. Backup ring

passages leading from hollow rotating

2-32

Hydraulic Systems

FM 5-499

Seal

Seal housing

Spring

lip

High

pressure

Back-up ring

Figure 2-43. T-ring seal

Figure 2-44. Lip seal

Seal ring

Cylinder

Piston

barrel

Cup seals

O ring

Cylinder

Piston

Figure 2-45. Cup seal

Figure 2-46. Piston ring

shafts. It is fine for high pressures but may not provide a positive seal. A positive seal is more likely to occur when piston rings are placed side by side. Often, a piston ring is

designed to allow some leakage for lubrication.

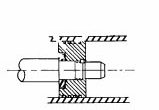

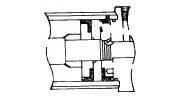

(8) Face Seal (Figure 2-47, page 2-34). This seal has two smooth, flat elements that run

together to seal a rotating shaft. One element is metallic and the other is nonmetallic. The elements are attached to a shaft and a body so that one face is stationary and the other turns against it. One element is often spring-loaded to take up wear. A face seal is used primarily when there is high speed, pressure, and temperature.

c. Packing. Packing is a type of twisted or woven fiber or soft metal strands that are packed between the two parts being sealed. A packing gland supports and backs up the

packing. Packing (Figure 2-48) can be either static or dynamic. It has been and is used as a rotating shaft seal, a reciprocating piston-rod seal, and a gasket in many static applications.

In static applications, a seal is replacing a packing. A compression packing is usually

placed in a coil or layered in a bore and compressed by tightening a flanged member. A

molded packing is molded into a precise cross-sectional form, such as a U or V. Several Hydraulic Systems

2-33

FM 5-499

packings can be used together, with a backup

that is spring-loaded to compensate for wear.

Housing

d. Seal Materials. The earliest sealing

materials for hydraulic components were

Sealing face

mainly leather, cork, and impregnated fibers.

Currently, most sealing materials in a hydrau-

Preloading

lic system are made from synthetic materials

spring

such as nitrile, silicone, and neoprene.

(1) Leather Seals. Leather is still a good

Shaft

sealing material and has not been completely

replaced by elastomers. It is tough, resists

abrasion, and has the ability to hold lubricat-

Low pressure

ing fluids in its fibers. Impregnating leather

High pressure

with synthetic rubber improves the leather's

sealing ability and reduces its friction.

Leather's disadvantages are that it tends to

squeal when it is dry, and it cannot stand high

temperatures.

Figure 2-47. Face seal

(2) Nitrile Seals. Nitrile is a compara-

tively tough material with excellent wearabil-

ity. Its composition varies to be compatible

with petroleum oils, and it can easily be

Compression

molded into different seal shapes. Some

packings

nitrile seals can be used, without difficulty, in

temperatures ranging from -40 degrees Fahr-

enheit to +230° F.

Pressure

(3) Silicone Seals. Silicone is an elas-

tomer that has a much wider temperature

range than some nitrile seals have. Silicone

cannot be used for reciprocating seals because

it is not as tough. It tears, elongates, and

abrades fairly easily. Many lip-type shaft

seals made from silicone are used in extreme

temperature applications. Silicone O-rings are

Figure 2-48. Compression packing

used for static applications. Silicone has a ten-

dency to swell since it absorbs a fair volume of

oil while running hot. This is an advantage, if

the swelling is not objectionable, because a seal can run dry for a longer time at start-up.

(4) Neoprene. At very low temperatures, neoprene is compatible with petroleum oil.

Above 150 degrees, it has a habit of cooking or vulcanizing, making it less useful.

(5) Nylon. Nylon is a plastic (also known as fluoro-elastomer) that combines fluorine

with a synthetic rubber. It is used for backup rings, has sealing materials in special applications, and has a very high heat resistance.

2-34

Hydraulic Systems

FM 5-499

CHAPTER 3

Pumps

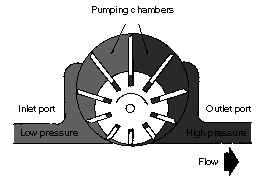

Hydraulic pumps convert mechanical energy from a prime mover (engine or electric

motor) into hydraulic (pressure) energy. The pressure energy is used then to operate an actuator. Pumps push on a hydraulic fluid and create flow.

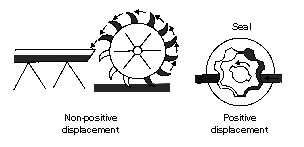

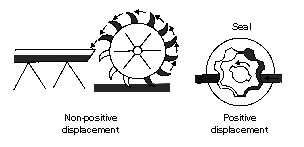

3-1. Pump Classifications. All pumps create flow. They operate on the displacement principle. Fluid is taken in and displaced to another point. Pumps that discharge liquid in a continuous flow are nonpositive-displacement type. Pumps that discharge volumes of liquid

separated by periods of no discharge are positive-displacement type.

a. Nonpositive-Displacement Pumps. With this pump, the volume of liquid delivered for each cycle depends on the resistance offered to flow. A pump produces a force on the liquid

that is constant for each particular speed of the pump. Resistance in a discharge line pro-

duces a force in the opposite direction. When these forces are equal, a liquid is in a state of equilibrium and does not flow.

If the outlet of a nonpositive-displacement pump is completely closed, the discharge

pressure will rise to the maximum for a pump operating at a maximum speed. A pump will

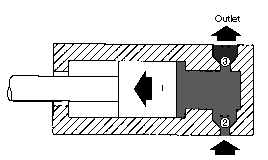

churn a liquid and produce heat. Figure 3-1 shows a nonpositive-displacement pump. A

water wheel picks up the fluid and moves it.

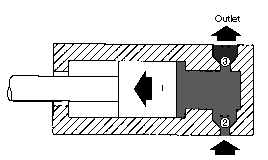

b. Positive-Displacement Pumps. With this pump, a definite volume of liquid is delivered for each cycle of pump operation, regardless of resistance, as long as the capacity of the power unit driving a pump is not exceeded. If an outlet is completely closed, either the unit driving a pump will stall or something will break. Therefore, a positive-displacement-type

pump requires a pressure regulator or pressure-relief valve in the system. Figure 3-2, page

3-2, shows a reciprocating-type, positive-displacement pump.

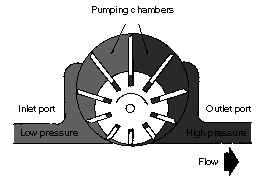

Figure 3-3, page 3-2, shows

another positive-displacement

pump. This pump not only creates

flow, but it also backs it up. A

sealed case around the gear traps

the fluid and holds it while it

moves. As the fluid flows out of

the other side, it is sealed against

backup. This sealing is the posi-

tive part of displacement. With-

out it, the fluid could never

overcome the resistance of the

other parts in a system.

c. Characteristics. The three

Figure 3-1. Nonpositive-displacement pump

contrasting characteristics in the

Pumps

3-1

FM 5-499

operation of positive- and nonpositive-displacement pumps are as follows:

•

Nonpositive-displacement pumps provide a smooth, continuous flow; positive-

displacement pumps have a pulse with each stroke or each time a pumping cham-

ber opens to an outlet port.

•

Pressure can reduce a nonpositive pump’s delivery. High outlet pressure can

stop any output; the liquid simply recirculates inside the pump. In a positive-

displacement pump, pressure affects the output only to the extent that it

increases internal leakage.

•

Nonpositive-displacement pumps, with the inlets and outlets connected hydrauli-

cally, cannot create a vacuum sufficient for self-priming; they must be started

with the inlet line full of liquid and free of air. Positive-displacement pumps often

are self-priming when started properly.

3-2. Performance. Pumps are usually rated according to their volumetric output and pressure. Volumetric output (delivery rate or capacity) is the amount of liquid that a pump can

deliver at its outlet port per unit of time at a given drive speed, usually expressed in GPM or cubic inches per minute. Because changes in pump drive affect volumetric output, pumps

are sometimes rated according to displace-

ment, that is the amount of liquid that

they can deliver per cycle or cubic inches

per revolution.

Pressure is the force per unit area of a

liquid, usually expressed in psi. (Most of

the pressure in the hydraulic systems cov-

ered in this manual is created by resis-

tance to flow.) Resistance is usually

caused by a restriction or obstruction in a

path or flow. The pressure developed in a

system has an effect on the volumetric

output of the pump supplying flow to a

system. As pressure increases, volumetric

Figure 3-2. Reciprocating-type, positive-

output decreases. This drop in output is

displacement pump

caused by an increase in internal leakage

(slippage) from a pump's outlet side to its

inlet side. Slippage is a measure of a

pump’s efficiency and usually is expressed

in percent. Some pumps have greater

internal slippage than others; some

pumps are rated in terms of volumetric

output at a given pressure.

3-3. Displacement. Displacement is the

amount of liquid transferred from a

pump’s inlet to its outlet in one revolution

or cycle. In a rotary pump, displacement

is expressed in cubic inches per revolution

and in a reciprocating pump in cubic

inches per cycle. If a pump has more than

Figure 3-3. Positive-displacement pump

3-2

Pumps

FM 5-499

one pumping chamber, its displacement is equal to the displacement of one chamber multi-

plied by the number of chambers. Displacement is either fixed or variable.

a. Fixed-Displacement Pump. In this pump, the GPM output can be changed only by

varying the drive speed. The pump can be used in an open-center system—a pump’s output

has a free-flow path back to a reservoir in the neutral condition of a circuit.

b. Variable-Displacement Pump. In this pump, pumping-chamber sizes can be changed.

The GPM delivery can be changed by moving the displacement control, changing the drive

speed, or doing both. The pump can be used in a closed-center system—a pump continues to

ope