56

Microsensors

Fig. 6. Fabrication processes of the photoelectronic magnetic microsensor with EM wave-

shielded packaging

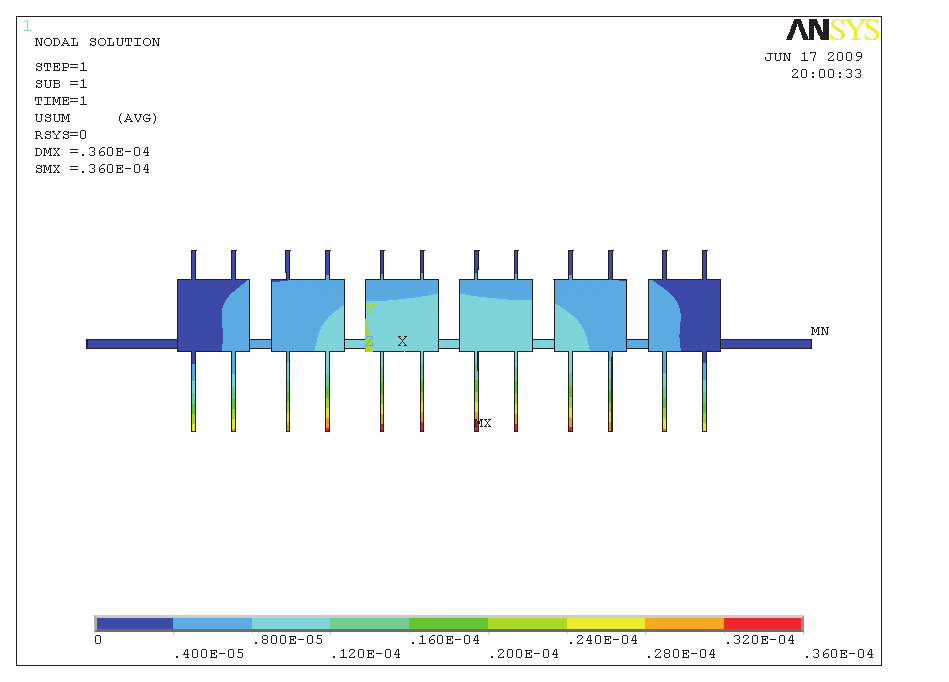

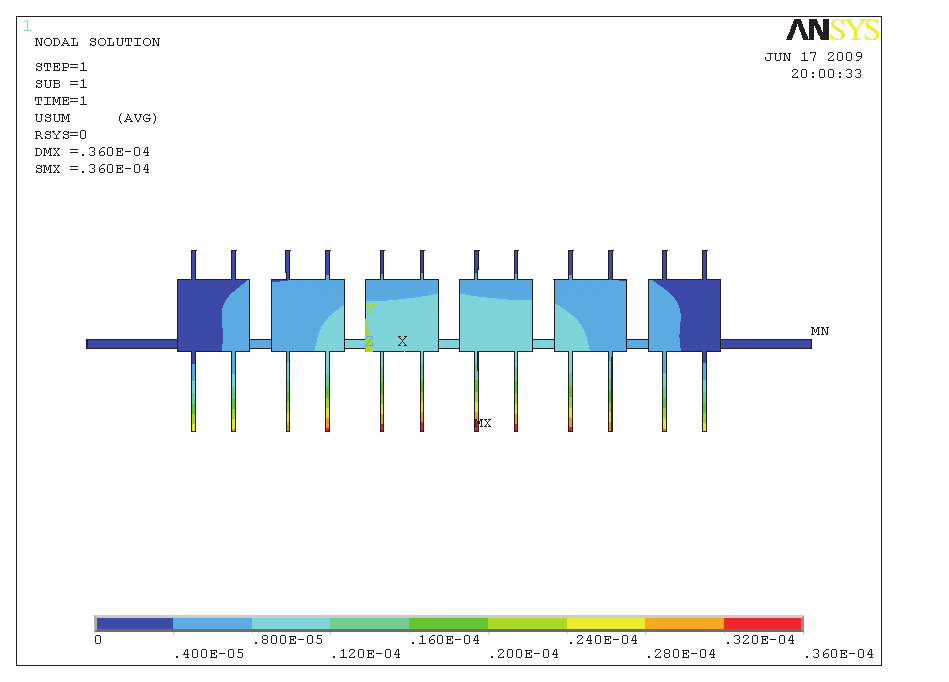

Fig. 7. FEM simulation using ANSYS to estimate cantilever bended conditions by magnetic

force

Photoelectronic Magnetic Microsensor with a Digit Readout

57

Fig. 8. Magnetic flux induced displacement related to different diameters of fibers

4. Measurement and analysis

The schematic cross-sectional view of the microsensor with interference reducing patterns

connecting with measurement blocks is shown in Fig. 9. When actuated by the magnetic

field, the membrane deflects to push fiber grating stretch that induce peak shift of the Bragg

wavelength. The stretched fiber induces Ni-Fe film deformation actuated by external

magnetic force that is the cause of fiber stretch to change the effective refraction index. The

peak shift amount of Bragg wavelength is proportional to radial magnetic force measured

using an optical spectrum analyzer with 0.01 nm resolution. Developed sensing structure of

the microsensor includes a 300 nm Fe-film coated on FBG fiber and a parallel-plate capacitor

both are deformed by a permalloy embedded polyimide membrane. Another measurement

block diagram in the schematic cross-sectional view of the developed photoelectronic

magnetic microsensor with temperature compensation is shown in Fig. 10. The sensing

mechanism is the FBGs actuated by the covered cantilevers that a ferromagnetic material is

topped on the surface. The cantilevers are attracted and bended to deform the optical

gratings by magnetic flux density from external Nd-Fe-B magnets. The peak shift of the

Bragg wavelength is produced from the major variations of the grating length and the fiber

core effective refraction index. A precision LCR meter (Agilent E4980A) is used to measure

magnetic induced capacitance variation because of the parallel interdigitated cantilever

bends. The measured electrical response is in the range of 1.22 to 38.25 pF that is applied as

a calibrating reference for comparing optical response excited by external magnetic flux. The

signal of position-dependent capacitances is very weak that can be processed by designing

capacitance-to-frequency transferred circuits to amplify magnetic response signal.

Instruments used in the optical-magnetic measurements are very expensive commercial

products. Therefore, to develop a precision, low cost, and portable measurement system is

desired. The angular-orientation interference measurement of the permalloy surrounded

packaging is shown in Fig. 11 to analyze environmental magnetic noise effect. The peak shift

amount of Bragg wavelength is proportional to vertical radial magnetic force measured

using an optical spectrum analyzer with 0.01 nm resolution. Original wave patterns of the