CHAPTER 3

FUEL BURNING EQUIPMENT

Section I. COAL STOKERS

3-1. General.

sion for driving the coal feed worm and electric

Stokers may be divided into four general classes:

motors supplying power for coal feed and air

underfeed, spreader, travelling or chain grate, and

supply. Air for combustion is admitted to the fuel

overfeed. Generally, domestic type boilers use

through tuyeres at the top of the retort. The retort

single-retort underfeed stokers and therefore, only

may be either round or rectangular. The stoker

this type is discussed.

feeds coal to the furnace intermittently in accord-

ance with temperature or pressure demands. A

3-2. Single-retort underfeed stokers.

special time or holdfire control is used to maintain

a fire during periods when heat is not required.

This unit consists essentially of a coal hopper, a

Figure 3-1 shows a typical arrangement.

screw for conveying coal from hopper to retort, a

fan which supplies air for combustion, a transmis-

Figure 3-1. Single retort screw feed stoker.

3-3. Operation.

and damage it. If too heavy, poor air distribution

Two main causes of excessive outage and mainte-

will result, causing spotty, uneven fire, holes in the

nance are sustained or frequent overloading of

fuel bed, smoke, and reduced efficiency. The

stoker and operating with insufficient draft. Where

correct depth of the fuel bed above the top of the

prolonged overloading is unavoidable, good

retort may be anywhere from 4 to 8 inches,

operation and careful attention to maintenance are

depending upon analysis and burning characteristics

important.

of the coal used.

a. Fire. Following are the main points to keep in

b. Draft. Check with draft gauge and a carbon

mind for maintaining a good fire.

dioxide (C0 ) indicator.

2

(1) Keep fire out of retort. This condition can

(1) Operate with a slight draft, preferably not

result from a fuel bed which is too thin, from

less than 0.02 inch water gauge just above the fuel

banking with insufficient fuel or from running with

bed. Positive pressure will cause excessive tem-

an empty hopper.

peratures at grates and lower wall areas.

(2) Avoid working the fire too much. If the fuel

(2) Maintain a proper supply of air at all times.

bed requires leveling off, use a light rake or bar on

Either too much or too little air will reduce

the surface of the fire. Never slice the fire as is done

efficiency and capacity.

in hand firing by pushing a bar under the fire and

(3) Do not force the stoker beyond the capacity

raising it through the fuel bed.

of the stack to carry away flue gases.

(3) Be sure to feed sufficient fuel when bank-

(4) Keep wind boxes properly sealed to prevent

ing. It may be necessary to renew the fuel supply

leakage of air into the ash pit and furnace.

during long banking periods.

(5) If the draft is insufficient, check leaks in

(4) The depth of the fuel bed is very important.

setting and losses through boiler and flue connec-

If too thin, the fire may burn down into the retort

tions. Check the position of the boiler damper.

3-1

TM 5-642

c. Cleaning.

moving parts. Where movement is transmitted by a

(1) Remove siftings from wind boxes often

shear pin or safety release be sure there is no

enough to prevent any possibility of fire under the

binding which prevents protective device from

hearth. Frequency of cleaning depends upon type of

serving its function. Make repairs or replacements

fuel used, but wind boxes should be inspected

promptly.

often.

c. When the stoker is shut down, make a thor-

(2) Keep the front of the stoker clean to pre-

ough inspection. Check for wear on moving parts

vent contamination of lubricants and excessive wear

and check alignment. Check condition of dump

on moving parts.

grates. On stokers equipped with moving grate

d. Lubrication. Use proper lubricants at suffi-

bars, check movement of bars to see that proper

ciently frequent intervals at all points requiring

clearances are maintained. Overall clearances to

lubrication to avoid unnecessary outages and ex-

provide for elongation of grate bars should be 1 ½

cessive maintenance. Prepare a definite schedule for

inches on small stokers, and up to 2 inches on

lubrication and adhere to it regularly. Manu-

larger stokers.

facturer*s literature should be consulted when set-

d. Inspection and maintenance procedures for

ting up the lubrication schedule.

anthracite coal stokers in domestic type installations

e. Lay-up. When stokers are to be out of service

are similar to that for bituminous coal stokers

for long periods of time, remove coal from the

previously described. However, some units are so

hopper and feed screw. Drain the transmission and

arranged that ash is automatically discharged to an

fill with the correct amount and viscosity the oil

ashpit, from which removal may be either manual or

recommended by the manufacturer. Clean and oil

by small automatic conveyor units. The tuyere

the motor using a good grade of electric motor oil.

surface of anthracite burners is made of either

Clean and paint the coal hopper with a rust-resist-

formed perforated sheet metal or cast metallic

ant paint; mix sawdust and fuel oil or crankcase

plates or rings with suitable air ports. In some

drainings and fill the feed-screw housing and retort.

instances tuyere surfaces are made of radially

This prevents moisture from forming on the feed

placed cast elements. Ignited coal is forced out

screw during idle periods. Have the controls

toward the periphery of the tuyere by the incoming

cleaned and adjusted as necessary by a competent

coal, and as burning is completed, the ash is

mechanic.

discharged by gravity from the ash ring into an

ashpit under the stoker retort. To avoid discharge

3-4. Inspection and maintenance procedures.

of unburned coal to the ashpit, adjust the rate of

Following is a description of good practices for in-

coal feed and air supply carefully.

spection and maintenance of coal stokers:

a. Inspect all accessible parts of the stoker often.

3-5. Troubleshooting underfeed stokers.

Inspect thoroughly at scheduled intervals.

A troubleshooting chart for underfeed stokers is in

b. During routine and daily inspections, look es-

appendix B.

pecially for loose bolts and loose connections in

Section II. HAND-FIRED COAL BURNERS

3-6. General.

stallations covered by this manual. Primary air

In coal burning installations, units may be hand

enters the lower portion of the furnace and passes

fired using either updraft or downdraft type fur-

up through the fuel bed. Stationary grate bars

naces. In both types, coal is fed manually onto

permit primary air to rise and ash to drop through.

grade bars forming the bed of the furnace. There

The fire must be cleaned manually with special

are limitations to the combustion capacity obtain-

tools. Sometimes dumping grates are used which

able with hand firing in a single heating unit; this

firing method is employed only with the smallest

permit mechanical removal of ash and refuse

units.

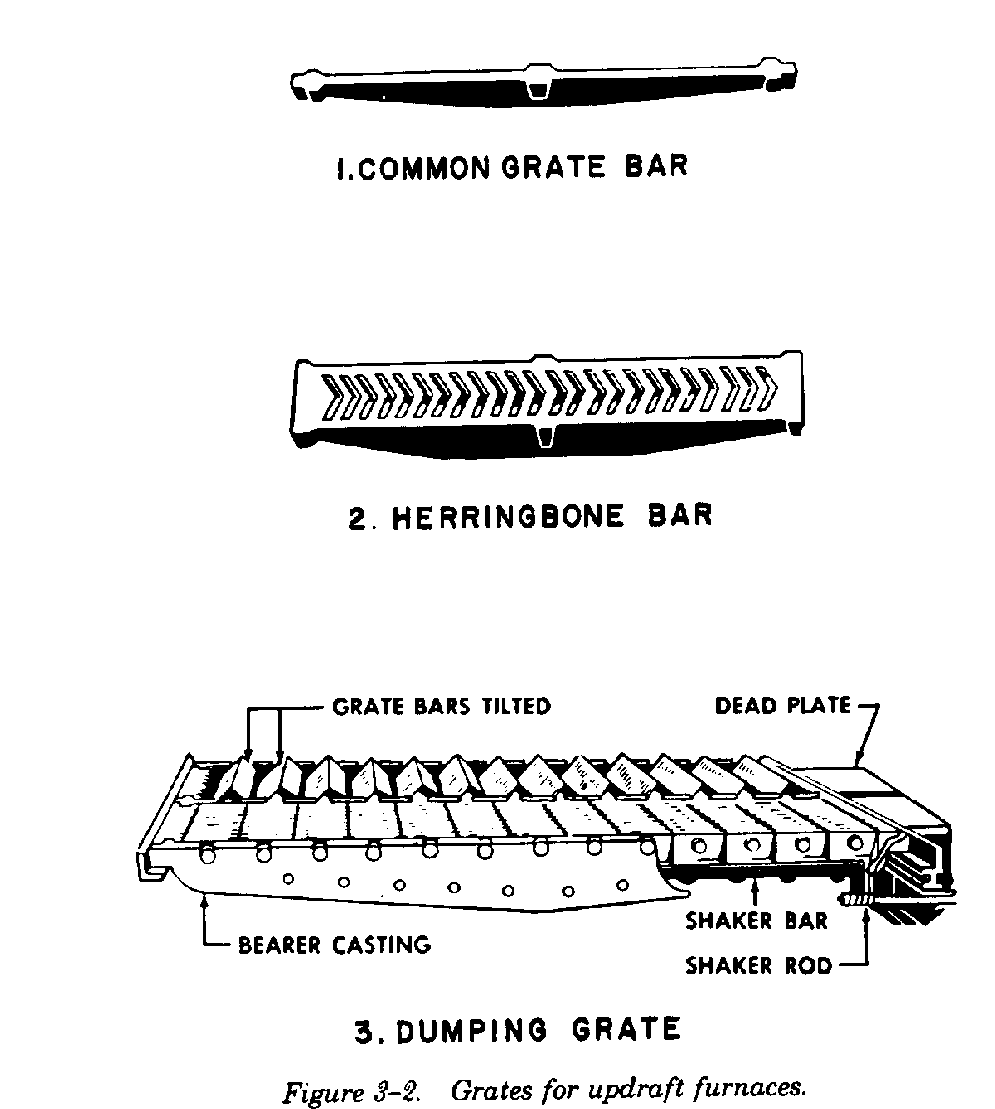

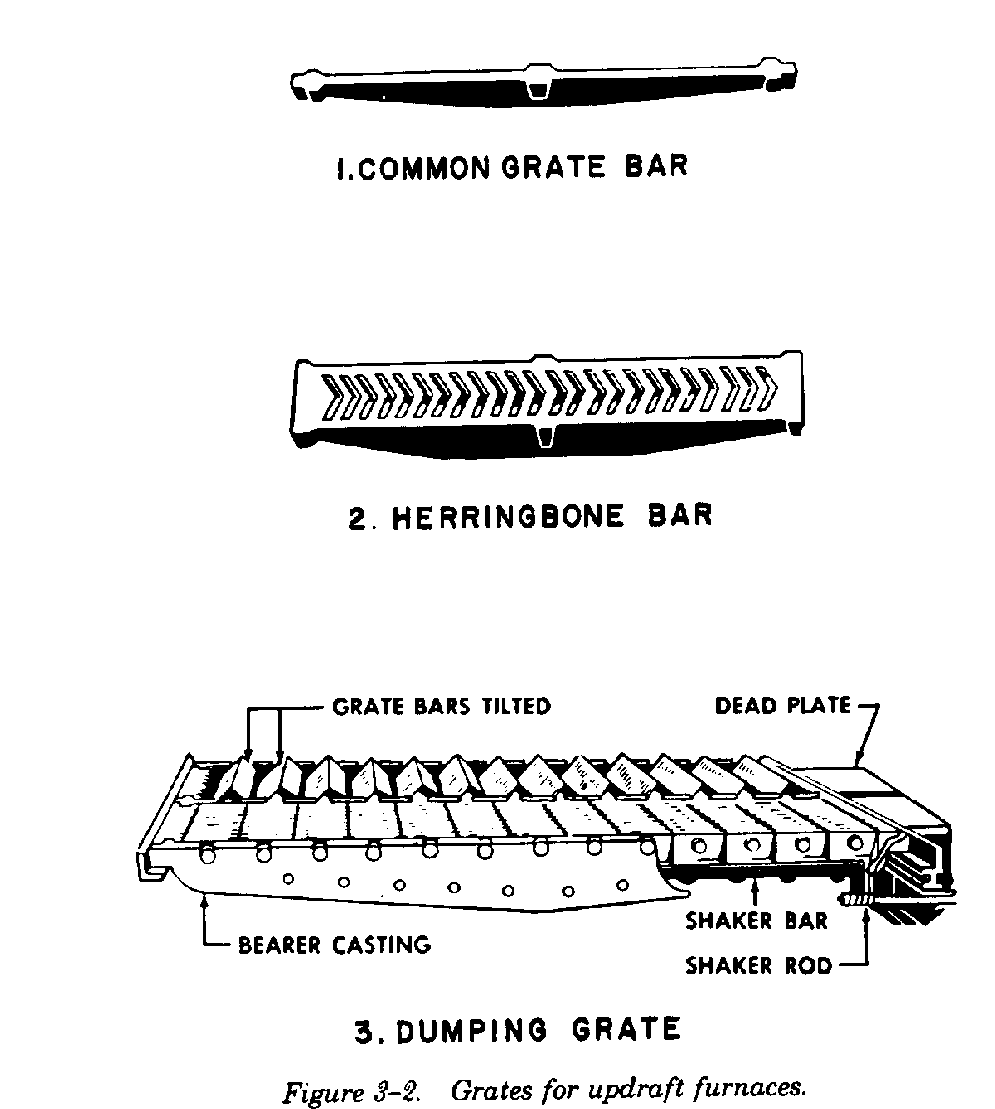

without opening fire doors. Typical grates used in

this type of furnace are shown in figure 3-2.

3-7. Furnace types.

a. Updraft furnace. Updraft type furnaces are

most commonly used in the types of military in-

3-2

TM 5-642

rise and the ashes to drop through.

(2) The herringbone or tupper bar (figure 3-2.2)

is about six inches wide with side flanges to prevent

warping. Each bar has V-shaped openings running

the length of the bar for passage of air and ash.

(3) The dumping grate (figure 3-2.3) permits

removal of the ash and refuse without opening the

firing doors and also reduces the amount of labor

required. Tools used to handle the fire are the hoe,

slice bar, and rake. The hoe and slice bar are used

to clean the fire and break the clinkers. The rake is

used to level off the fuel bed. The bridge wall keeps

the fire on the grates, assists in mixing the air and

gases, and directs them over the heating surface.

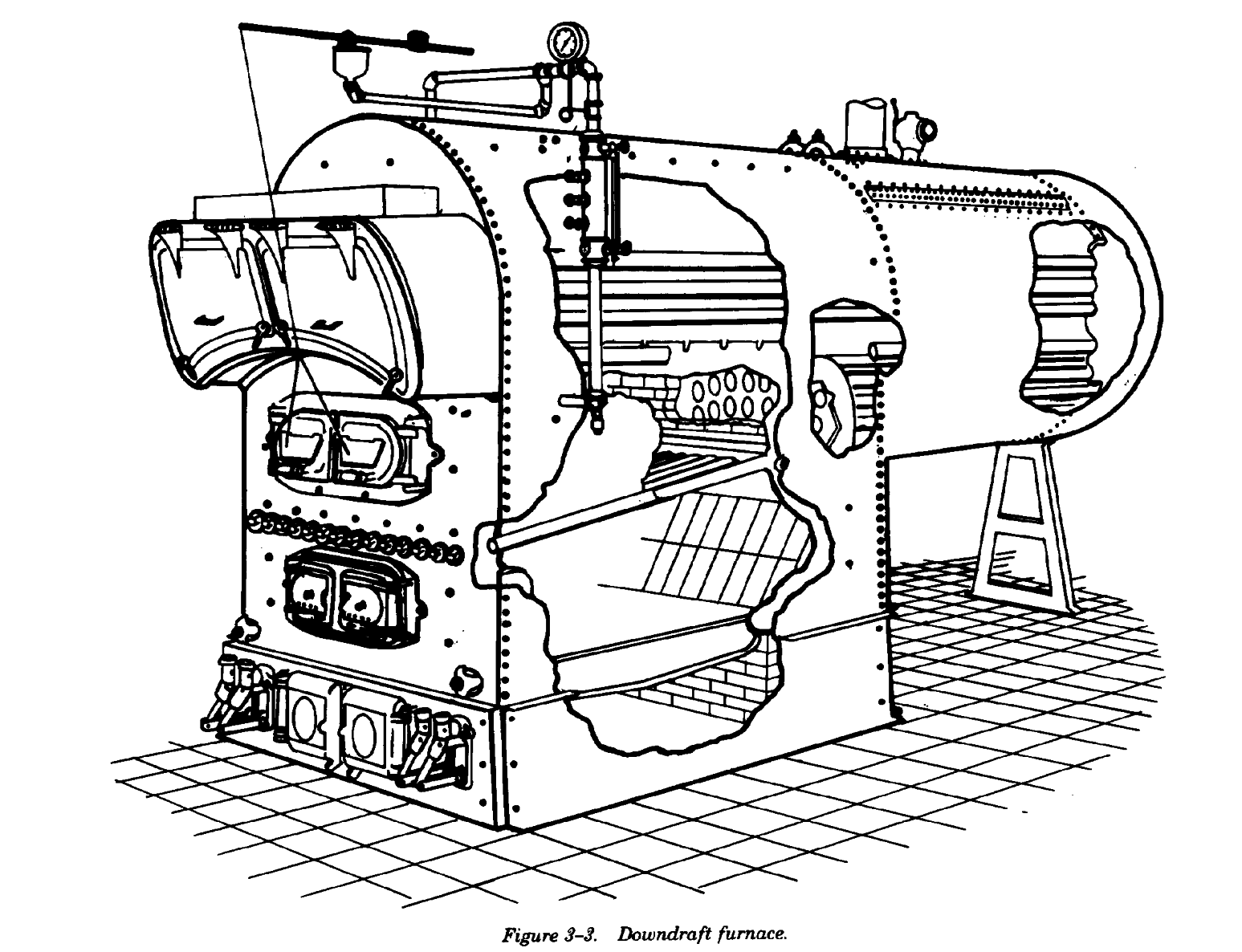

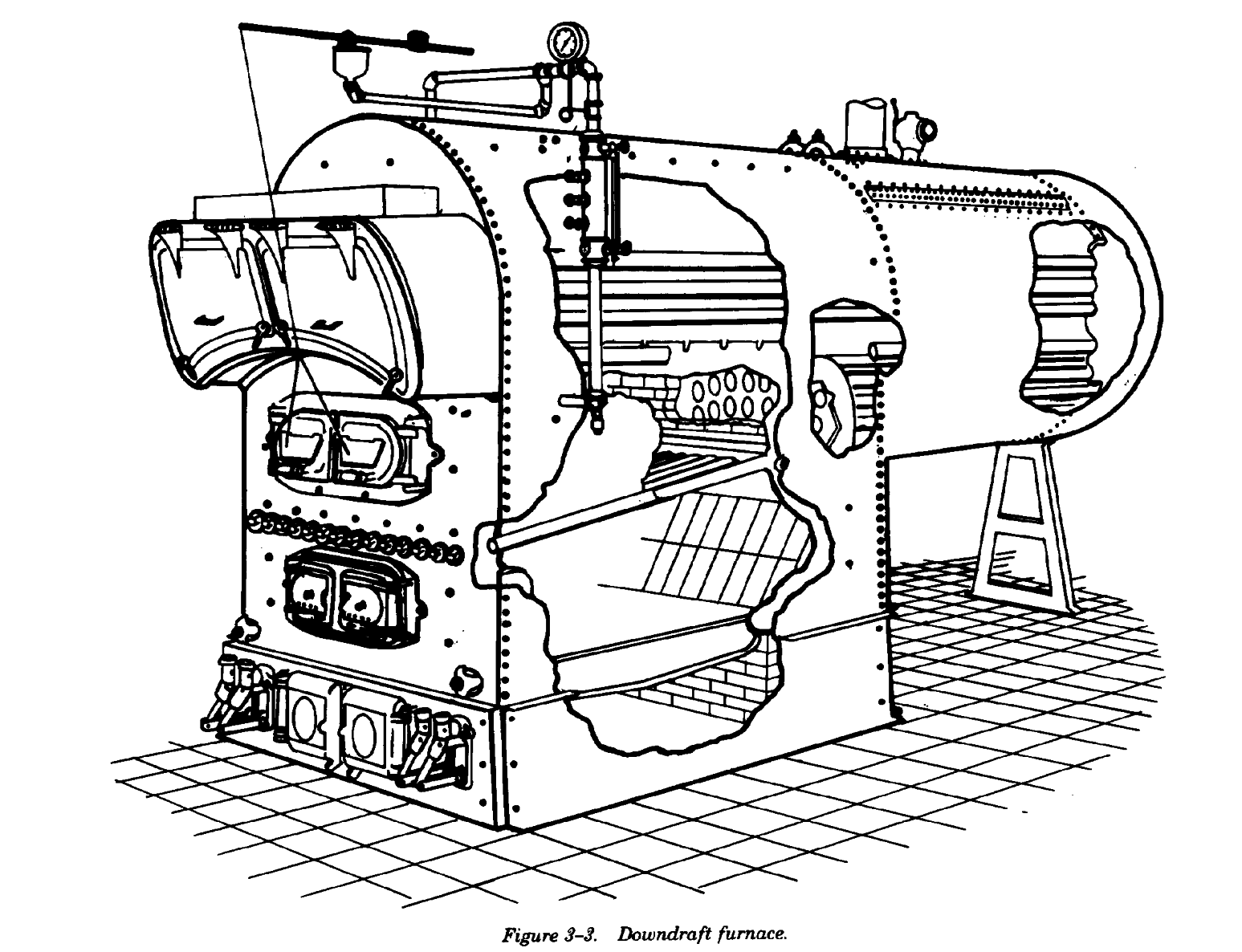

b. Downdraft furnace. The downdraft furnace

(figure 3-3) has both an upper and lower grate and

gets its name from the fact that primary air passes

down through the fuel on the upper grate. The

upper grate consists of a series of tubes which

extend from the front water leg to a header in the

rear. This header extends from one side water leg

to the other, and supports a refractory wall which

forms the back of the downdraft furnace. The lower

grate is formed by common grate bars or by a

regular shaking grate. Coal is fired through the top

The grate, which supports the fuel bed and admits

doors onto the upper or downdraft grate where it

air for combustion, is made up of a number of bars

burns. Incandescent fuel drops through to the lower

supported at the rear by the bridge wall and at the

grate where it keeps a bright fire. Air is admitted

front by a dead plate which, in turn, is supported by

above the upper grate and mixes with the distilled

the brickwork. The grate bars are held in place by

gases from the coking coal as it passes down

their own weight. The types of grates commonly

through the upper grate. The incandescent fuel bed

used for updraft furnaces are the common grate

on the lower grate helps to complete the

bar, herringbone or tupper bar and dumping grate.

combustion of volatile matter given off by the coal

(1) The common grate bar (figure 3-2.1) is usu-

and reduces emission of smoke from the boiler.

ally about three feet long and three inches deep at

This type of furnace cannot be used where high

its center. The width varies from ¾ inch at the top

rates of firing are necessary.

to ¾ inch at the bottom. This grate allows the air to

3-3

TM 5-642

3-8. Operation.

bed. After the distillation is complete, the

In hand firing, the best condition of the fuel bed is

remaining carbonized fuel is pushed back and

obtained when coal is fired frequently, in small

distributed over the bed. This method, while

amounts, with proper distribution; when caked

effective, does not permit obtaining high rates of

masses are broken up immediately; and when ash

combustion compared to the other methods.

and clinkers are not allowed to clog the bed. In

(1) The best firing condition for a hand fired

general, there are three methods of hand firing.

furnace is obtained when fresh coal is added at or

a. Spread firing. A small amount of the fresh

shortly after completion of distillation of the previ-

coal is distributed evenly each time over the entire

ous charge. Optimum intervals between firing are

surface of the bed. This method is commonly

approximately ten minutes for bituminous coals,

adopted with anthracite and other low-volatile

and slightly less frequently for less volatile semi-

coals.

bituminous and anthracite coals.

b. Alternate firing. New coal is placed on select-

(2) The bed thickness for best results depends

ed areas of the grate each time. The coal may be

on many factors, including the kind, size and con-

placed alternately on one half of the grate, on al-

dition of coal, the characteristics of the ash, the

ternate strips, or on alternate spots. This method of

draft available and the loading. In general, with

stoking is particularly suited to non-caking coals.

natural draft, bed thicknesses range from four to

c. Coking-firing. Fresh fuel is placed on the

eight inches with run-of-mine bituminous coal and

front edge of the fuel bed and allowed to cake

with anthracite buckwheat. Bed thicknesses range

there, the volatile matter passing back over the hot

from 10 to 14 inches for semibituminous coals.

With heavy loading, however, it may be desirable to

3-4

TM 5-642

use a relatively thin fuel bed to increase the flow of

cases, bed thickness for a given type of furnace and

primary air obtainable with the available draft. In all

coal is best determined by experiment.

Section III. OIL BURNERS

3-9. General.

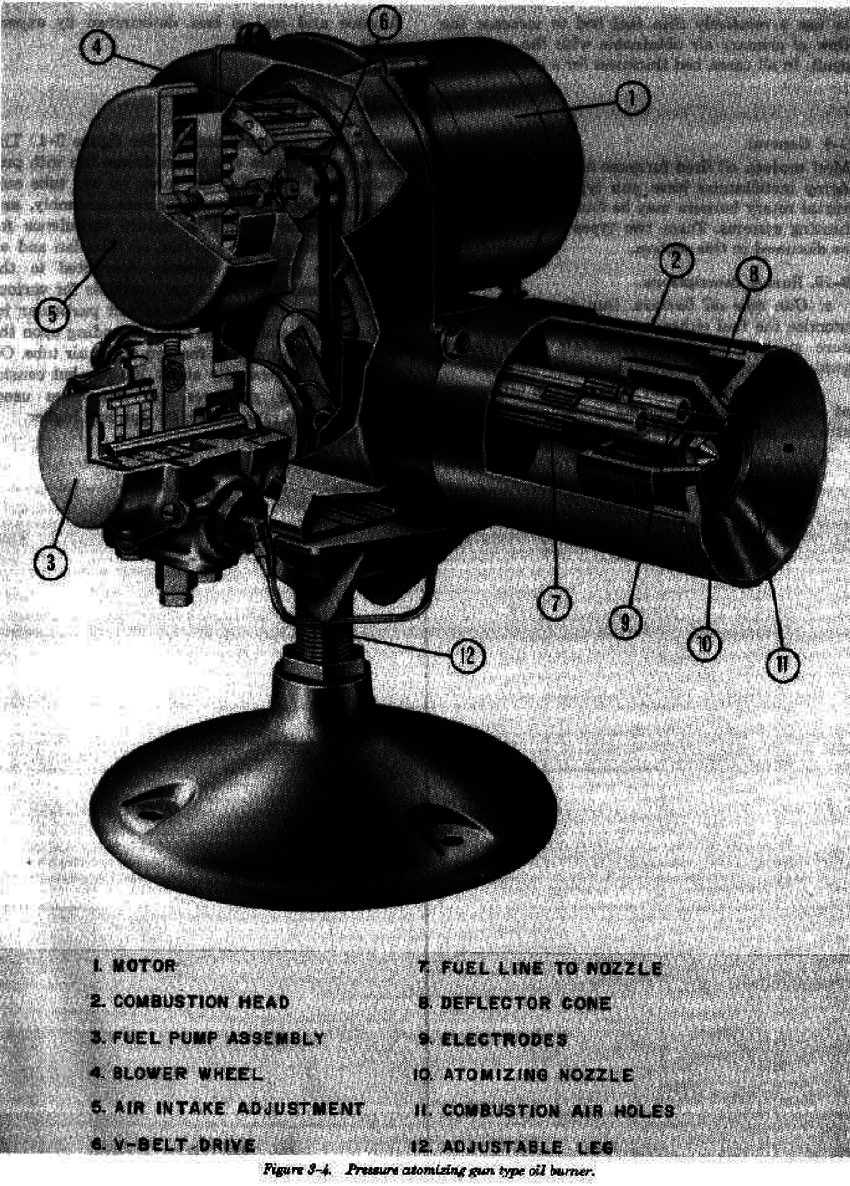

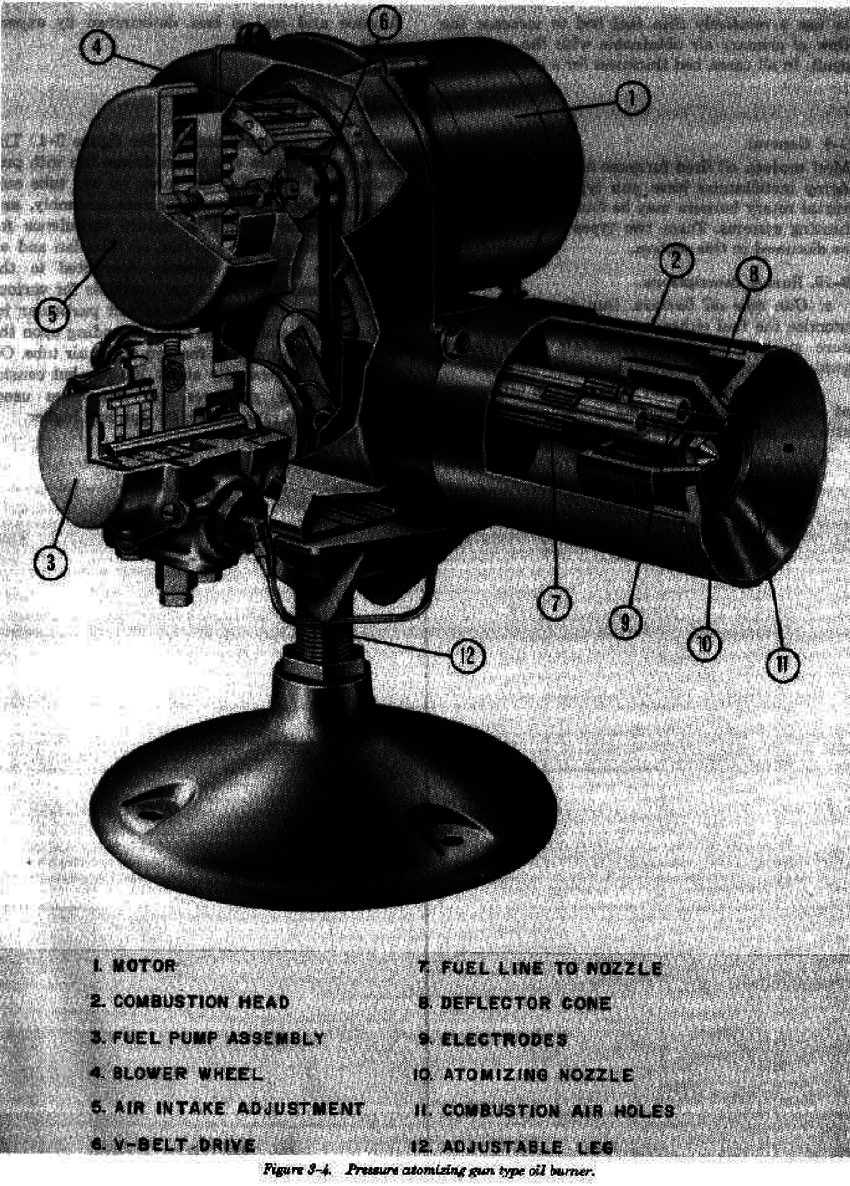

valve, and atomizing nozzle. (See figure 3-4.) The

Most modern oil fired furnaces and boilers used at

air system consists of a power-driven fan with pro-

Army installations have gun type burners. Hori-

vision to throttle the air inlet, an air tube sur-

zontal rotary burners may be found on some older

rounding the nozzle and electrode assembly, and

heating systems. These two types of burners will be

vanes or other means to induce turbulence for

discussed in this section.

proper mixing of air and fuel oil. The fan and oil

pump are generally directly connected to the motor.

3-10.

Burner descriptions.

Atomizing nozzles are available for various spray

patterns and oil rates to suit particular installations.

a. Gun type oil burners. Gun type oil burners

Flame shapes vary depending upon the design of

atomize the fuel either by oil pressure (high-pres-

the air exit at the end of the air tube. Oil pressures

sure gun) or by low-pressure air (low-pressure

are generally about 100 psi, but considerably

gun).

greater pressures are sometimes used. Burner

(1) High-pressure gun burners. The oil system

output ranges from 0.5 gph and higher.

of a high-pressure atomizing burner consists of a

strainer, pump, pressure-regulating valve, shut-off

3-5

TM 5-642

3-6

TM 5-642

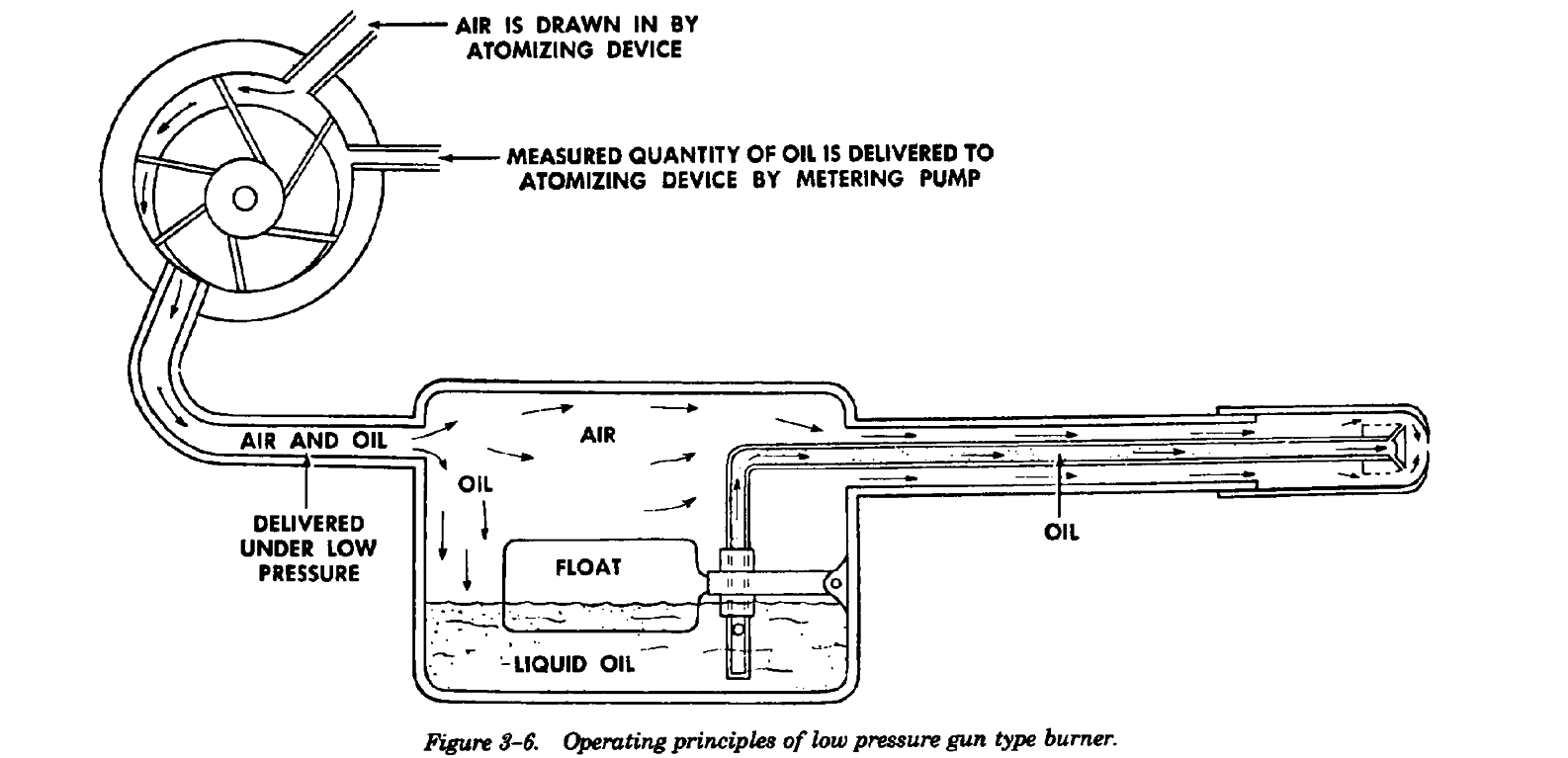

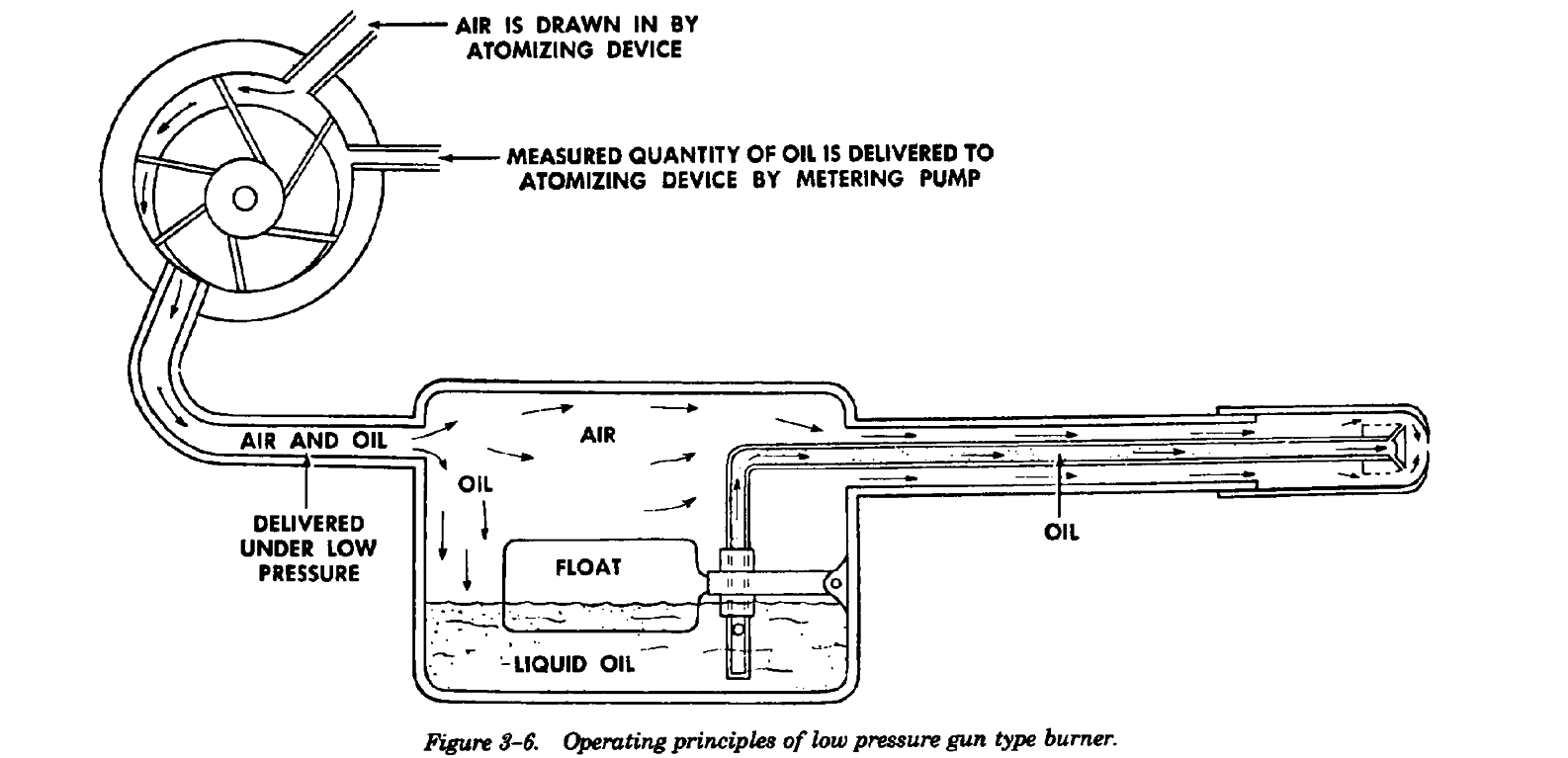

(2) Low-pressure gun burners. This gun type

means to deliver the air and oil to the nozzle. The

burner uses a portion of the combustion air at rel-

oil pump delivers the fuel oil at low pressure. The

atively low pressures to mix with the fuel oil at the

nozzle opening is relatively large because of the low

nozzle orifice. Expansion of the compressed air

pressure and the increased volume of the air-oil

froths or emulsifies the oil and a fine spray is de-

mixture. Electric ignition is almost exclusively used.

livered into the combustion chamber. The form and

Electrodes are located near the nozzle, but out of

parts of the low pressure air-atomizing burner, as

the path of the oil spray. Minimum burner output is

shown in figures 3-5 and 3-6 may be similar to

approximately 20 gph so that this type burner is

those of the high-pressure atomizing burner except

used only for very large furnaces.

for the addition of a small air compressor and

Figure 3-5. Air atomizing gun type burner.

3-7

TM 5-642

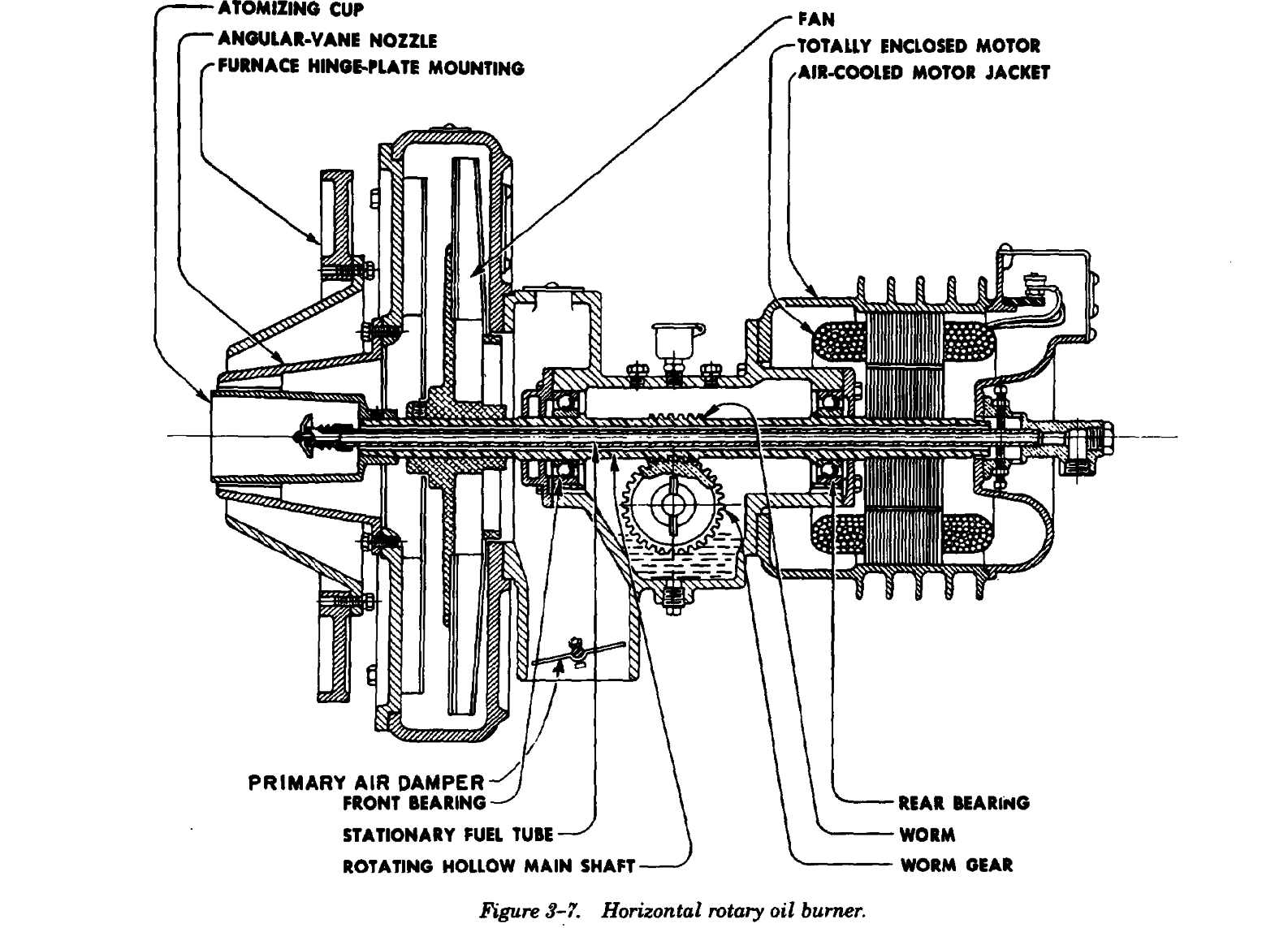

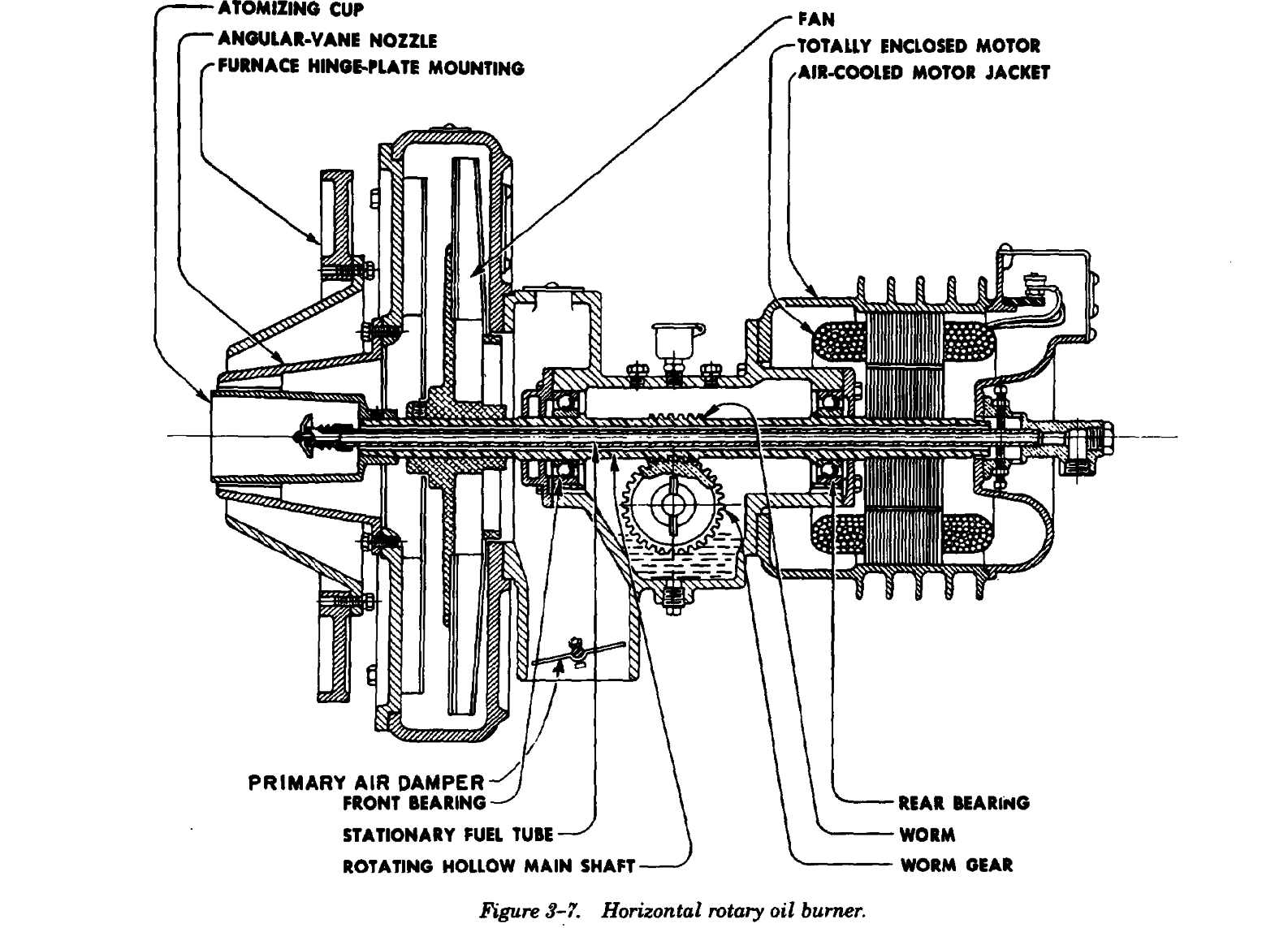

b. Horizontal rotary burners. Horizontal rotary

surrounding the atomizing cup which shapes the

burners (figure 3-7) originally designed for com-

flame and mixes the air with oil. In the turbine

mercial and industrial use, are used for domestic

driven type, part of the air is first passed through a

heating in smaller sizes. In this burner, oil is

turbine which rotates the cup, and is then directed

atomized in a conical pattern by being sprayed from

to properly shape the flame. Horizontal rotary

a rapidly rotating cup. Oil is delivered to the cup by

burners are constructed to swing away from the

pump or gravity. There are two types of horizontal

furnace for inspection and cleaning. This type of

rotary burners, those in which the cup is rotated by

burner employs gas-electric or gas pilot ignition and

a directly connected electric motor and those in

operates satisfactorily with a fairly wide range of

which the cup is driven by an air turbine. In the

fuels. Large size burners are able to atomize heavier

motor driven type, air is forced through vanes

oils.

3-8

TM 5-642

3-11.

Ignition procedures.

(2) Partly close air shutter.

Domestic oil burners vaporize and atomize the oil

(3) Check pressure gauge and petcock installa-

and deliver a predetermined quantity of oil and air

tion.

to the combustion chamber for combustion. Oil

(4) Make a cold contact in primary burner con-

burners for boilers and warm air furnaces operate

trol or stack switch by tilting contact carrier to left

automatically and maintain a desired temperature.

so contact closes. See instructions from supplier of

a. Oil pressure. Pressure must be sufficient to

primary control for this operation.

properly atomize the fuel oil and to provide flow of

(5) Close burner switch with thermostat and

fuel to the atomizing head at a minimum velocity

limit control calling for heat.

consistent with efficient operation. Generally, No. 1

(6) Open petcock to expel air from system.

oil will work well in small burners provided it

Close when oil flow is clear.

contains a lubricant to lubricate the pump. A com-

(7) If burner stops before oil reaches nozzle, let

paratively heavy oil will allow flow through a given

safety element in stack control cool before pushing

nozzle somewhat in excess of the rating stamped on

button to restart. Do not hold relay in because

the nozzle. Heavy oils require 100 psi pressures.

safety element will become overheated.

High pressure plus heavy oil tends to raise the flow

(8) Slowly open air adjustment until fire burns

rate considerably above the nozzle marking. If the

clean.

flow is too heavy, a smaller nozzle should be

(9) If oil initially discharges into the firebox

installed.

without igniting because of ignition difficulty or

b. Burner starting The following procedure

other cause, oil will soak into the soft brick. Be

should be followed to start a gun-type or horizontal

sure relief door is open. Properly ventilate combus-

rotary burner.

tion chamber after any misfire. When burner does

(1) Set draft for 0.02 to 0.04 inch water gauge.

ignite, shut burner off immediately and allow sur-

3-9

TM 5-642

plus oil to burn off. Oil-soaked brick will cause the

operates at high flame, and changes to low flame

burner to rumble and puff for a few minutes until

when room temperatures reach a desired point. A

oil has completely burned out. After any misfire,

modification to this system provides for three

personnel should stand to one side of the opened

ranges of firing.

relief door to avoid injury from possible backfire.

c. Continuous. In the continuous system, the

(10) Make final air adjustment after burner has

flame burns continuously but the rate is regulated

been running long enough to warm the fire-pot.

manually or automatically to meet the heating load.

Look through the barometric draft regulator with a

droplight. Reduce the supply of burner air until

3-13.

Inspection and maintenance of oil

smoke can be seen passing through the light ray in

burners.

the smokepipe. Then open the air adjustment until

a. Equipment. Each serviceman should have the

smoke disappears.

items listed below to start or to service gun-type

(11) After the burner has been visually adjusted

and horizontal rotary burners.

and allowed to run for approximately 30 minutes,

(1) Pressure gauge set consisting of 150 psi

reduce the stack draft until there is just enough

pressure gauge, fittings and petcock for purging air

pressure in the firebox to prevent possible increases

from oil line when starting the burner. Pressure

under unfavorable draft conditions. The draft

gauges with ranges as high as 600 psi may be

regulator helps maintain a constant draft regardless

required for high-pressure gun burners.

of outside weather conditions. Adjust the draft by

(2) A full set of Allen setscrew wrenches for the

properly setting the adjuster. Too little draft is

bypass plugs and for adjusting the nozzle holder

likely to cause firebox pressure, odors in the

and electrodes. Use only a socket wrench of proper

building and possible smoke or smothering of the

size for the nozzle. An open end S-wrench is

flame. Excessive draft accentuates the effect of a

required for nozzle holders.

possible leak, lowers the percentage of CO in the

2

(3) Small screw driver for adjusting pressure at

flue gas, and in turn reduces the overall efficiency

regulator and for installing and servicing the

of the unit. After burner flame and draft are

thermostat.

properly adjusted, flue-gas analysis should show a

(4) Pipe dope for use with oil lines. Be sure that

CO content o