INTRODUCTION

1-1. Purpose and scope.

systems in good operating condition. This includes

a. This technical manual provides basic infor-

keeping equipment information files and necessary

mation for facilities personnel regarding the oper-

records of the maintenance work performed.

ation and maintenance of small heating systems and

related equipment. Generally, the manual covers

1-5. Systems overview.

low pressure steam boilers (less than 15 psig), low

The main heat conveying media for space heating

pressure hot water boilers (less than 30 psig), space

systems are steam, hot water, and warm air.

heaters, unit heaters, and warm air furnaces. The

a. Steam. Water heated to the boiling point

term “small” is used in the context of this manual to

evaporates and produces steam as long as heat is

differentiate from the high pressure systems and

added. If the heat is removed or reduced, evapora-

equipment that are covered in detail in TM 5-650,

tion will stop or decrease. The quantity of heat

Central Boiler Plants.

contained in each pound of steam depends on its

b. This manual makes reference to specific types

pressure and temperature. Steam can be generated

of equipment commonly in use at Army installa-

and used as either saturated or superheated steam.

tions. System and equipment descriptions contained

Chapter 4 gives detailed information on steam

in the manual are general in nature. Equipment

systems.

manufacturers* technical literature and manuals

(1) Saturated steam. For each steam pressure,

should also be used for reference, training, and

there is a specific temperature at which the steam

troubleshooting specific equipment.

will become saturated. When steam is saturated, a

drop in temperature or an increase in pressure will

1-2. References.

cause part of the steam to revert to water. There

Related publications are listed in Appendix A.

are two types of saturated steam: dry, i.e., without

moisture; and wet, which is intermingled with

1-3. Abbreviations and terms.

moisture, mist or spray. Saturated steam is

Abbreviations and special terms used in this manual

commonly used for space heating and process heat.

are explained in the Glossary.

(2) Superheated steam. When steam has a

temperature higher than its corresponding satura-

1-4. Organization and responsibility.

tion pressure, it is called superheated steam. The

The operating and maintenance personnel for

difference between the temperature of superheated

heating systems are organized in accordance with

steam and its saturation temperature is called the

the applicable Army regulations and staffing guides.

superheat. Usually, superheated steam is generated

Supply and administrative support are provided by

in central heating plants when necessary to avoid

other divisions, branches, and/or sections within the

condensation in the steam lines of the plant and the

Directorate of Engineering and Housing. There are

distribution system, or to drive steam turbines.

significant differences at the installations in the

Normally in such instances, not more than 50F

quantity, type, and use of equipment. Therefore,

superheat is imparted to the steam.

personnel responsibilities may vary locally to

(3) Total heat content. A certain amount of

provide the necessary operating and maintenance

heat is needed to change water into steam. The

functions. In some cases, an individual may well

specific amount depends on the initial condition of

perform both operation and maintenance. In all

the water and the desired pressure and temperature

instances, coordination is required with the work

of the steam. The amount of heat required to

management functions (planning, estimating,

convert water at 32F into steam at a specific pres-

scheduling, recording data, etc.).

sure and temperature is called the total heat content

a. Operating personnel. Operating personnel

(or enthalpy) of the steam at that particular

have the responsibility to fire the equipment in the

pressure and temperature. As pressure rises from

most efficient and economical manner. This in-

atmospheric conditions up to about 450 psia, the

cludes the performance of equipment adjustments

total heat content of dry saturated steam increases.

and simple routine maintenance work consistent

At higher pressures, the total heat decreases as

with good operating practice.

b. Maintenance personnel. Maintenance person-

pressure increases. However, superheating

nel have the responsibility to maintain heating

increases the total heat content of the steam at any

1-1

TM 5-642

pressure. Any thermodynamic steam table will show

the areas where heating is required. Chapter 6 gives

the total heat content of steam at different pressures

detailed information on warm air systems.

and temperatures.

1-6. Energy conservation policy.

b. Hot water. Hot water is a very useful carrier

of heat. Circulating in a closed system, the water

a. All Army installations should have a manage-

absorbs heat in a boiler or heat exchanger and re-

ment improvement program that includes policies

leases it to the heat using equipment. Hot water

and guidelines relating to the efficient use and

systems can be classified as high temperature,

conservation of utilities. Conservation measures

medium temperature, and low temperature. Chap-

should be implemented by supervisory, operating

ter 5 gives detailed information on hot water sys-

and maintenance personnel and by the users. The

tems.

importance of keeping equipment properly used,

adjusted, and maintained cannot be overempha-

(1) High temperature water. High temperature

sized.

water (HTW), above 350F is usually generated in

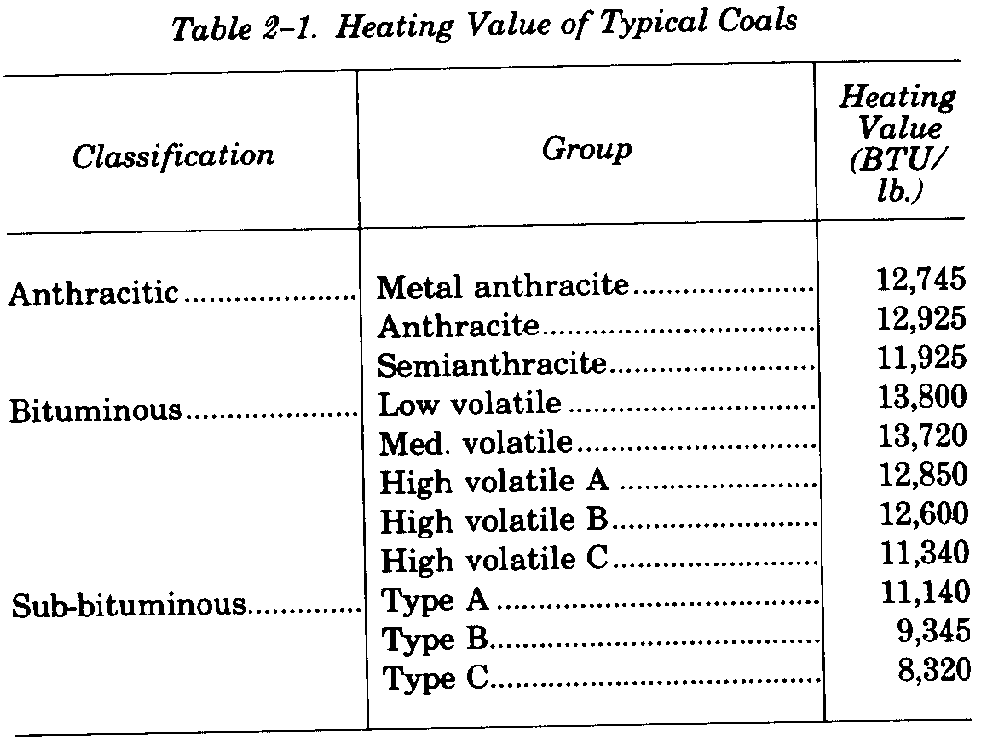

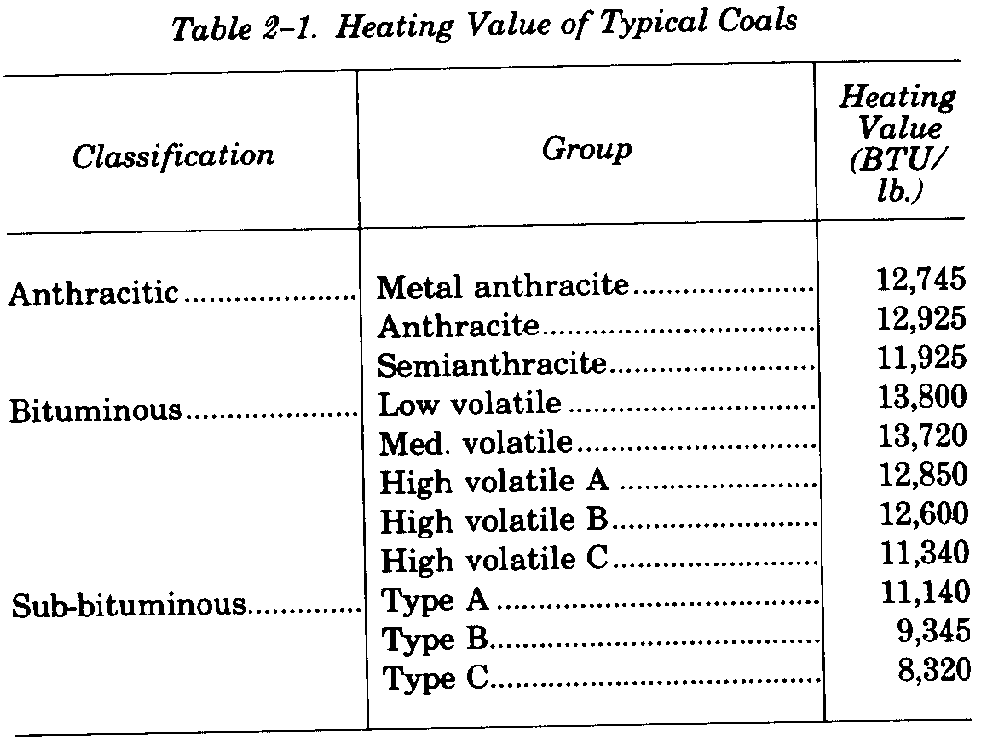

b. Periodic reviews should be made of all factors

central heating plants and then delivered to the

influencing fuel selection to determine whether the

consumers by a distribution system. A heat ex-

fuel used still remains the most cost efficient for a

changer is normally used in each building to convert

particular installation. Also, the feasibility of

the HTW into low temperature water for use in

improving or modernizing firing methods for cur-

space heating.

rent fuels should be considered.

(2) Medium temperature water. Supply water

c. The greatest boiler operating efficiency is ob-

temperature for this type system ranges from 250F

tained when units are operated at or near their full

to 350F and is used for distribution systems, large

load ratings. Therefore, two boilers should never be

space heaters, absorption refrigeration, and indus-

operated if one can carry the load without

trial purposes.

exceeding its rating. Supervisors should review

(3) Low temperature water. Supply water tem-

daily operating logs to insure proper boiler oper-

perature for this type system is below 250F and is

ation. Give specific attention to the percentage of

used for space heating. Generally, this manual

CO in the flue gas and temperature of the gas.

2

covers low temperature hot water systems and

These are good indicators of operating efficiency

and depend on the proper balance between the rate

equipment.

of fuel feed, combustion air supply, draft, and stack

c. Warm air. Unlike steam and hot water, which

temperature.

are fed through pipes to space heating equipment

d. Periodically inspect heated facilities. Observe

from which heat is dispensed by radiation and

thermostat settings and advise users when incorrect

convection, warm air supplies direct heat. In warm

settings are found. Correct settings may be posted.

air systems, the cold air is heated by blowing it

Also, identify those facilities where excessive heat

through a furnace casing or heat exchanger. The

is lost due to improper insulation and open doors or

warmed air is then distributed through air ducts to

windows and take corrective actions.

1-2

TM 5-642