apron), or a combination of the two. It extends outward

restoration of a facility to such a condition that it can be

from the shore into a harbor or other navigable waters to

effectively utilized for its designed purpose. The repair

permit berthing along one or both sides of its length.

is accomplished by overhaul, reprocessing, or

replacement of constituent parts or materials that have

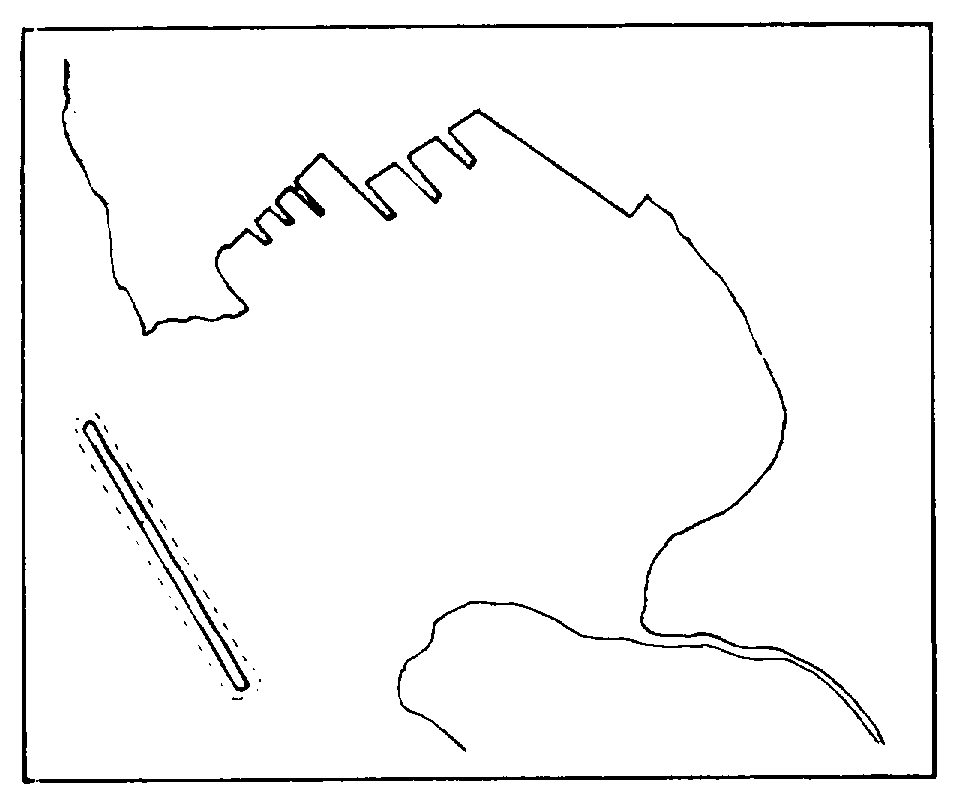

1.4.2.2 Wharf. A wharf or quay (Figure 1-2) is a deck

deteriorated by action of the elements or usage and

structure supported above the water on piles (open type),

have not been corrected through maintenance. Repair

can be incorporated in a concurrent modernization

program.

1-4

Figure 1-1. Open-type pier.

a solid-fill structure retained by bulkheads (closed), or a

combination of the two. It runs parallel to the shore and

is connected to it at more than one point (usually

continuously) to provide berthing normally along one

side.

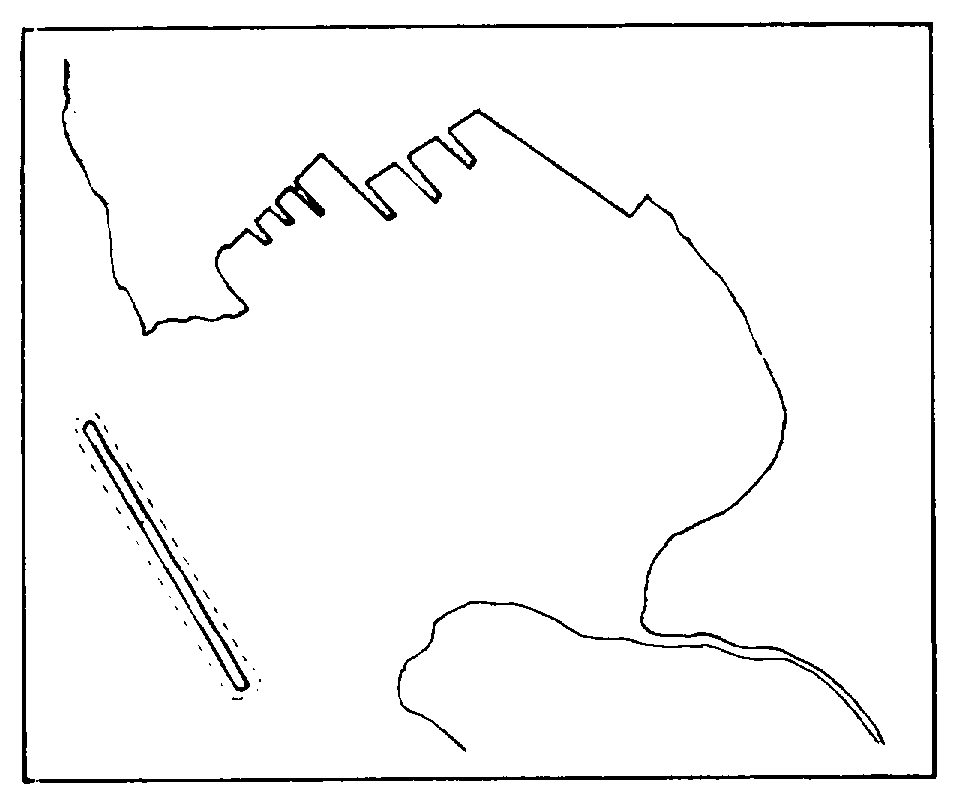

Figure 1-3. Example of a dolphin.

1.4.2.4 Fleet Mooring. A fleet mooring is an offshore

ship anchoring system that consists of a ground tackle

arrangement of chain or cable, sinkers, and anchors or

other holding devices placed on the bottom of an

anchorage. It is connected by means of a riser chain (or

chains) to a buoy (riding on the surface of the water)

Figure 1-2. Example of a wharf.

whereby a ship can be made fast to the buoy.

Maintenance of fleet moorings is described in Reference

1.4.2.3 Dolphin. A dolphin (Figure 1-3) is a structure

1-17; it is mentioned in this manual only to identify fleet

usually consisting of one or a group of piles. It is placed

moorings as an important type of waterfront structure

near piers and wharves or in turning basins and ship

requiring regular maintenance.

channels (1) to guide vessels into their moorings, (2) to

fend vessels away from structures, shoals, or the shore,

1.4.2.5 Drydocking System. A drydocking system is a

(3) to support navigation aids, or (4) to moor a vessel.

facility for exposing the normally underwater portion of a

ship for construction, inspection, modification, repair, or

1-5

hull maintenance. Several different types are listed

below.

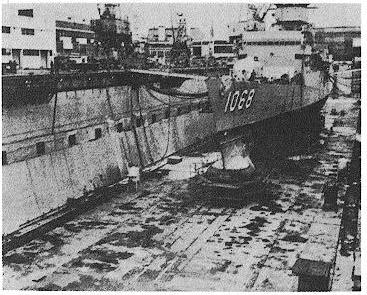

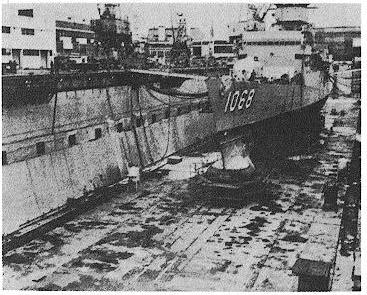

1.4.2.5.1 Graving Dock. A graving dock (Figure 1-4) is

a fixed basin usually of stone masonry, concrete, or

piling cells adjacent to the water's edge. It can be

closed off from the waterway by a movable watertight

barrier (entrance caisson or flap gate). It can, therefore,

be pumped dry, allowing a ship to settle down on

blocking set on the dock floor.

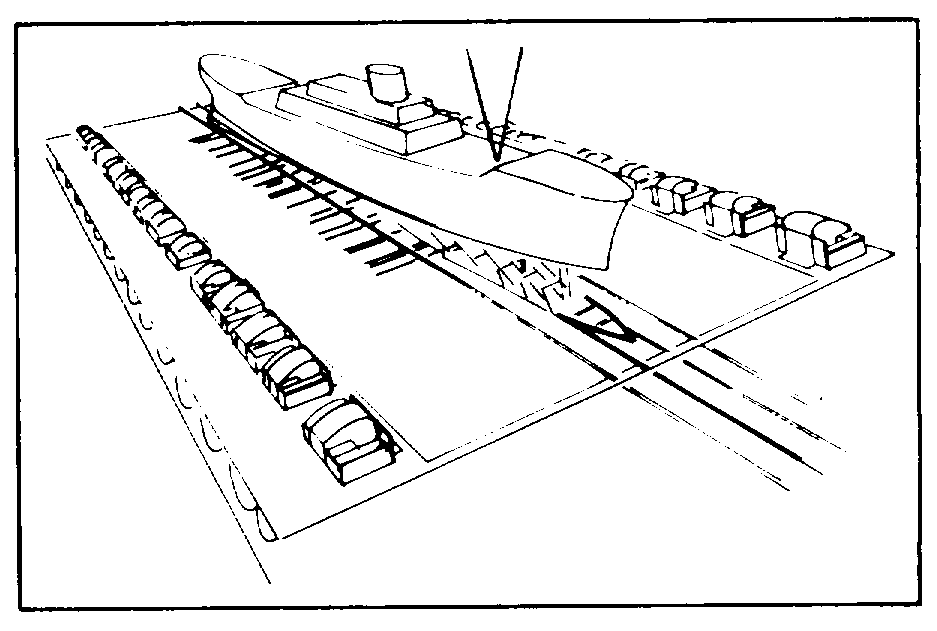

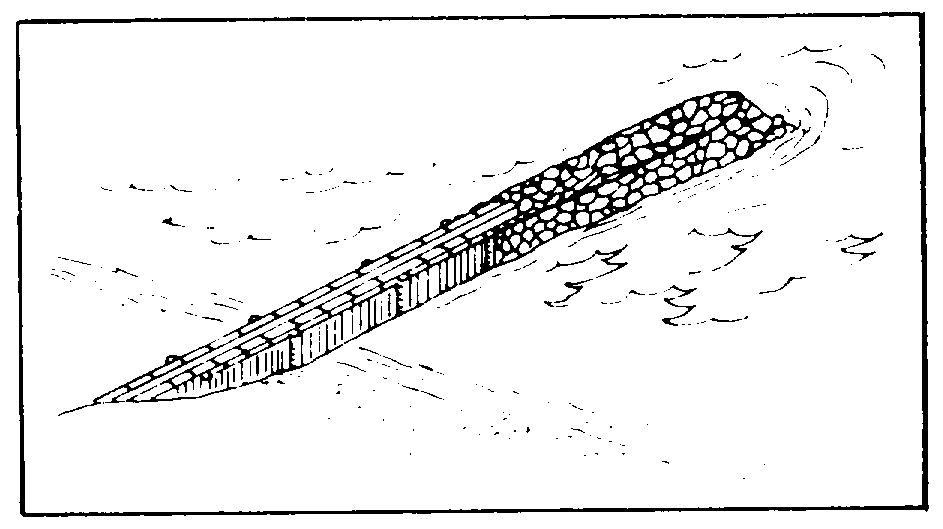

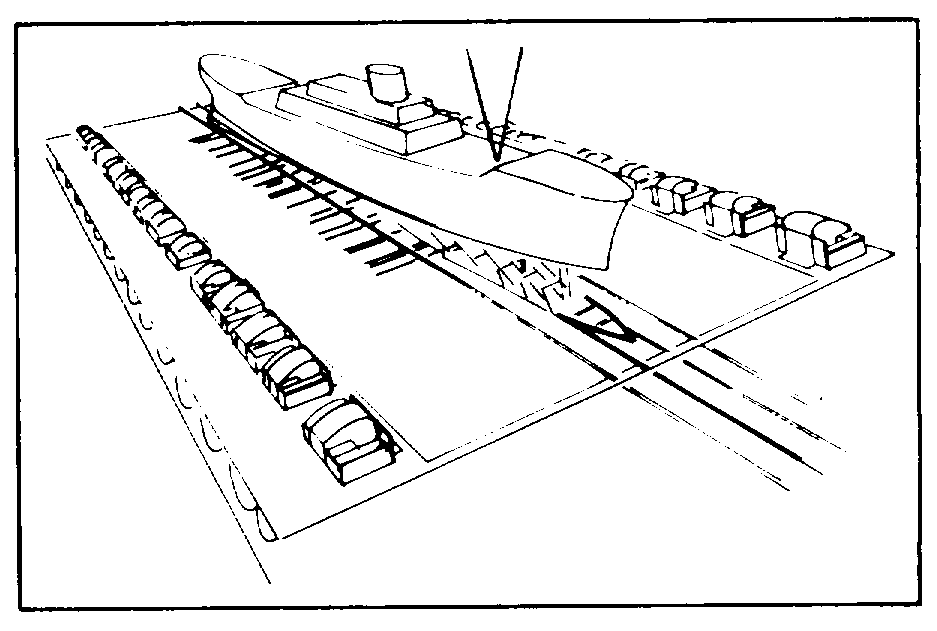

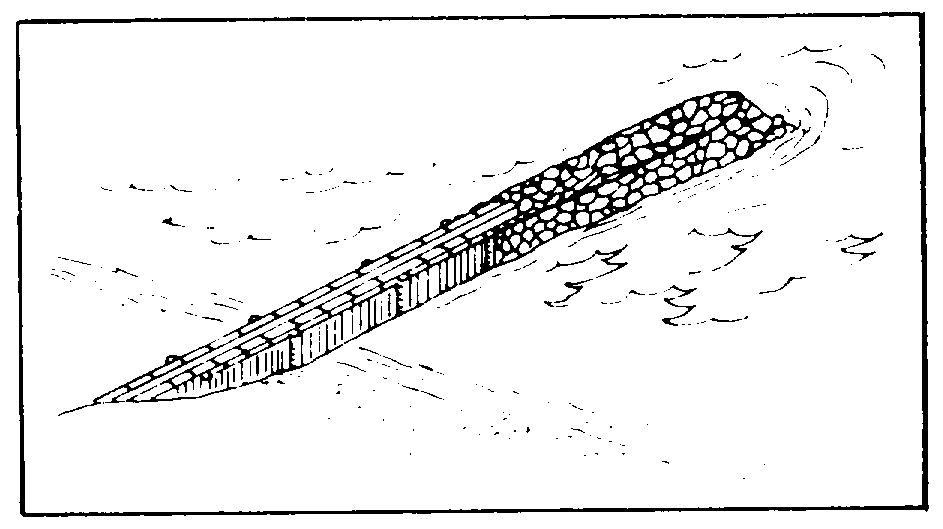

Figure 1-5. Example of a marine railway.

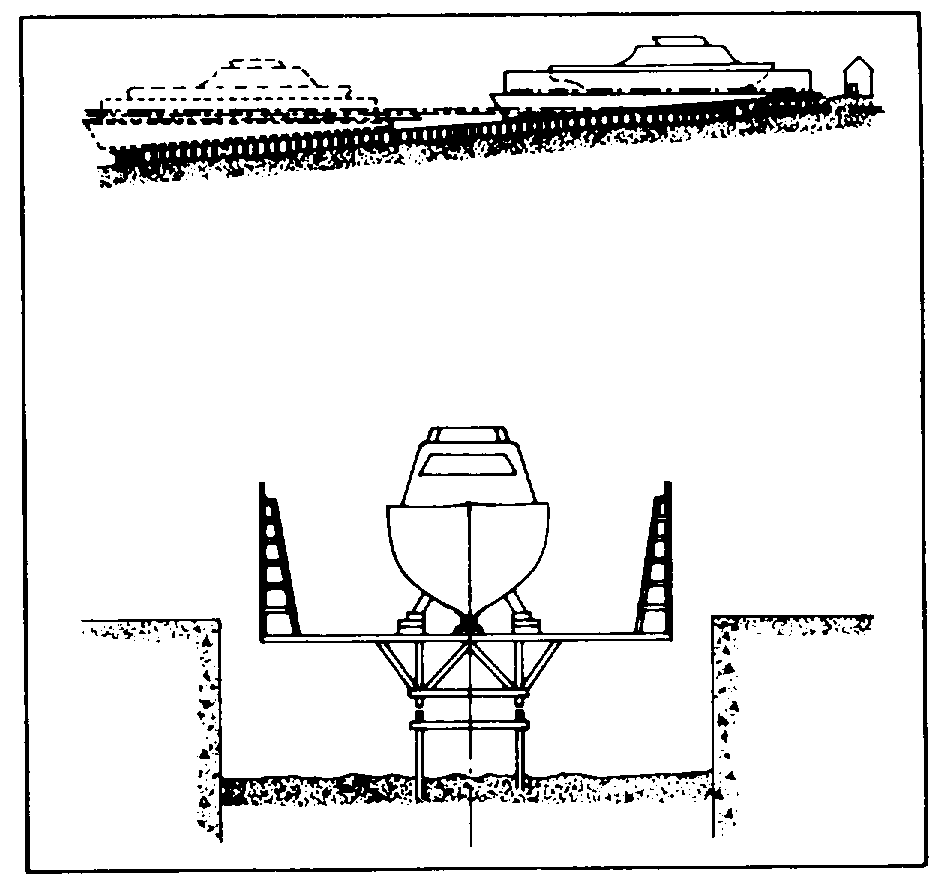

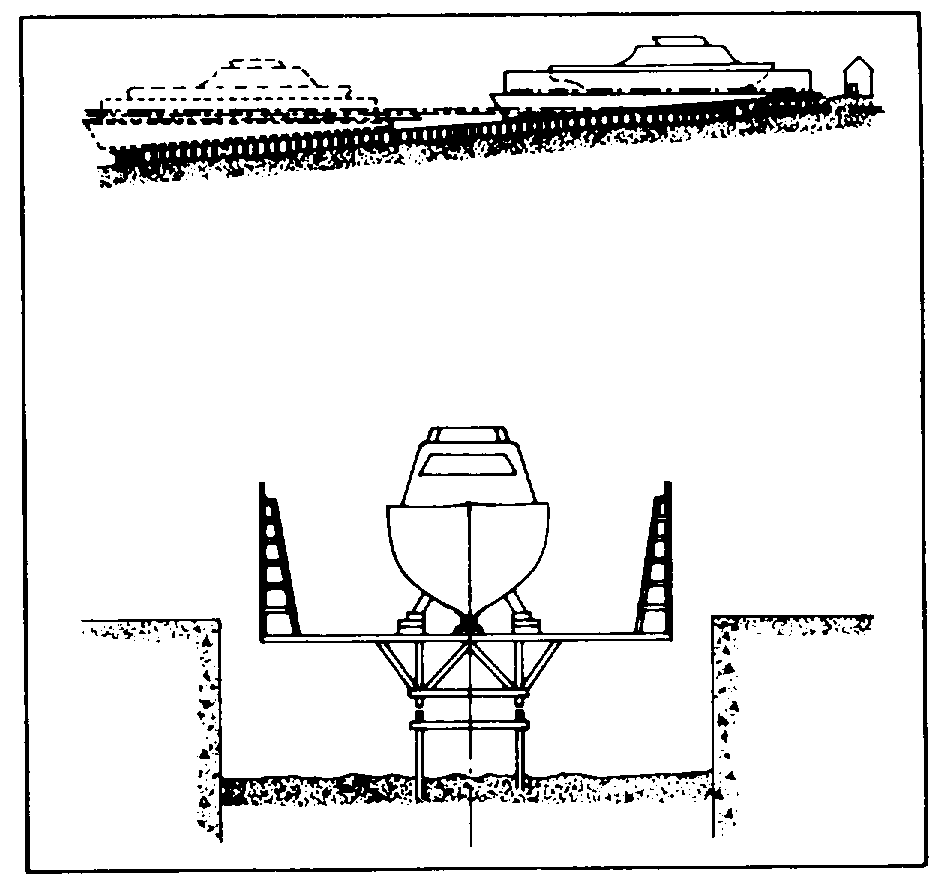

1.4.2.5.4 Vertical Lift. A vertical lift drydock (Figure 1-

6) is a platform which is lowered into the water to

receive a ship, and then elevated out of the water by

electrically, pneumatically, or hydraulically powered

hoisting equipment.

Figure 1-4. Graving dock with ship installed.

1.4.2.6 Quay Wall. A quay wall (Figure 1-7) is a barrier

1.4.2.5.2 Floating Drydock. A floating drydock is a

of steel, stone, concrete, or wood that supports an

ship or U-shaped structure that can be submerged by

embankment or fill built as a part of a waterfront

flooding to permit a vessel to enter and then later be

structure.

pumped dry to raise the vessel out of the water.

Maintenance and operation of floating drydocks will not

be discussed in this manual.

1.4.2.5.3 Marine Railway. A marine railway (Figure 1-

5) consists of an inclined groundway extending into the

water, a mobile ship cradle on wheels or rollers,

groundway ship cradle tracks, hoisting machinery, and

chains or cables for hauling the ship cradle endwise or

sidewise.

Figure 1-6. Example of a vertical lift

drydock.

1-6

1.4.2.8 Jetty. These structures, which are located at the

entrance to a harbor or in a river estuary, extend from

the shore into deeper water to prevent the formation of

sandbars and to direct and confine the flow of water due

to currents and tides (Figure 1-9). Jetties are usually

constructed of mounds of large rubble to an elevation

several feet above high tide. They are generally lower

in height than breakwaters and are designed to offer

less resistance to waves than breakwaters and seawalls.

Jetties should be dense enough to prevent sand from

entering the entrance channel.

Figure 1-7. A quaywall.

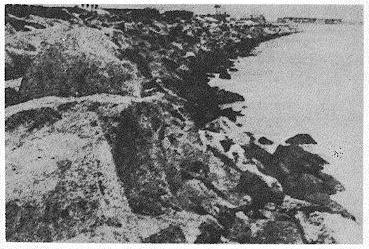

1.4.2.7 Mole. Moles are normally earthen structures

that extend outward from shore into the navigable

waters of the harbor (Figure 1-8). The sides and

offshore end of a mole are retained or protected by

riprap, sheet-pile bulkhead of either prestressed or

reinforced concrete, or a gravity-type wall of either

masonry or concrete. Such a structure is sometimes

used as a breakwater. Generally, the level top is

appreciable in area and may contain paved roads,

Figure 1-9. Example of a jetty.

railroads, and crane trackage. If the sides and offshore

end of a mole are protected by either a bulkhead or a

1.4.2.9 Breakwater. These are substantial structures,

gravity-type wall, the structure can be used to berth

located at the outer limits of a harbor or anchorage, to

vessels, provided the depth of water is adequate.

protect the inner waters against the effects of heavy

seas and winds and to ensure safe mooring, operating,

loading, or unloading of shipping within the harbor

(Figure 1-10). These durable barriers usually consist of

rubble-mound structures and are often covered with

heavy, large rocks or reinforced concrete armor units.

There are three general types of breakwaters,

depending on type of exposed face: (1) vertical, (2)

partly vertical and partly inclined, or (3) inclined.

Breakwaters may be either detached from the shore or

shore-connected.

Figure 1-8. Example of a mole.

1-7

1.4.2.11 Seawall. These are massive structures, built

along and parallel to the shoreline, that are designed to

protect coastal areas against erosion caused by wave

action and flooding during heavy seas (Figure 1-12).

The seawalls are constructed of rubble-mound, granite

masonry, or reinforced concrete. They are usually

supplemented with steel or concrete sheet pile driven

into the beach and strengthened by wales and brace-

type piles.

Figure 1-10. Example of the placement of

a breakwater.

1.4.2.10. Groin. These structures control the rate of

shifting sand by influencing offshore currents and wave

action in a manner such that erosion of the shoreline is

prevented or minimized (Figure 1-11). Generally, the

Figure 1-12. Example of a seawall.

longtime effect of groins is an increase in the width of

the beach. These narrow structures may be

perpendicular to the shoreline and are constructed of

large rocks (at least 1 ton each), precast concrete units,

reinforced or prestressed concrete piles, steel sheet

piles, or timber cribbing filled with rock. The most

common type of groin is the high, dense one that is

designed to catch the drifting sand until the sand is

forced around the offshore end.

Figure 1-11. A groin.

1-8

SECTION 5.

1.5.1 PROGRAMMING. The maintenance program for

waterfront structures and other harbor facilities shall be

1.5.3 CAUSES OF DETERIORATION. The

developed to include the prevention and prompt

deterioration of waterfront facilities is caused

detection of deficiencies or damage and the quick

PLANNING by exposure to destructive forces, such as:

performance of maintenance or repairs in an

economical and workable manner. Replacement or

(1)

Attack by fungi, termites, and marine

repair of damaged parts should be made as soon as

organisms

possible because when one item is not working, the

(2)

Corrosion

remaining parts are more easily damaged. These

(3)

Mechanical damage, including the impact

requirements are essential to the maintenance

and pressure of ships and cargo and the abrasive action

standards established by higher authority.

of sand, ice, and debris

(4)

Erosion due to wind and wave action,

1.5.2 ECONOMIC REQUIREMENT. In the

tides, water currents, rain, snow, sleet and ice, and

maintenance of waterfront facilities thorough

freezing and thawing.

consideration shall be given to the overall economy of

the facility. Of particular importance is a complete study

1.5.4 INSPECTION. Waterfront facilities shall be

of the replacement cost of the facility in relation to the

inspected periodically to determine the extent of the

expected life span and the cost of repairs. Other factors

maintenance and repair work required. References 1-1

to be considered include the following: prompt detection

and 1-16 set up the Navy's guidelines for inspection and

of deficiencies or damage and the expeditious

include essential information on guides, check-off forms,

performance of maintenance or repairs in an

reports, and record systems to be used in the program.

economical and workable manner. Replacement or

It is recommended that inspections be made annually of

repair of damaged components should be made as soon

all basic structures and more frequently for fenders and

as possible because of:

movable equipment, such as brows and camels.

Additional inspections may be necessary under certain

(1)

Possible obsolescence of the facility

circumstances, such as tidal waves, high tides,

(2)

The present adequacy of the facility

earthquakes, typhoons, heavy freezes, etc. Inspections

(3)

The present and future availability of

may be made from the structures, from a boat or float,

maintenance funds

or from below the water line by divers. (See Appendix A

(4)

The operational economics of downtime

for details on diver inspections.) Underwater television is

involved in major repair or replacement of facilities.

often employed in visual inspections.

1-9

SECTION 6. PREPARATION FOR WORK

1.6.1 FIELD MEASUREMENTS. During inspections,

wear, corrosion, alignment, deflection, etc. may be

1.6.3 SKETCHES. As a part of programming the

estimated. Where there is any question as to the

repairs, sketches should be made to outline clearly the

degree of hazard, an accurate engineering investigation

extent, sequence, and details of the repair operation.

shall be made. Facilities to be repaired shall be

On other than major projects, freehand sketches,

carefully measured so that construction details can be

properly dimensioned and supplemented by notes, will

designed and estimates of required materials prepared.

be sufficient to permit an experienced maintenance man

Material storage areas should be designated and laid

to carry out the work properly. All sketches should be

out at this time so that interference with traffic is

clear and legible and should normally be reproducible.

minimized. Field measurements should include the

Copies of the sketches, properly identified as to location

exact location of underground utilities so that they can

and date, should be filed with the job record and with the

be avoided or relocated as necessary.

as-built drawings.

1.6.2 AS-BUILT DRAWINGS. “As-built" drawings, if

1.6.4 CHECKING STRUCTURAL STABILITY. Any

available, should be used in programming the repairs

evidence of damage or deterioration affecting the

rather than the original drawings, because these

structural stability of any facility should be the subject of

drawings should show all deviations from the original

an immediate engineering study. This study should

design and changes made during the original

include the degree of hazard and recommendations as

construction. These drawings should be carefully

to what corrective measures are required.

compared with actual field observations to detect any

changes that might have been made after completion of

the as-built drawings.

SECTION 7. ACCESS TO WORK

1.7.1 DIVERS. No one skill is more essential to the

1.7.2 RAFTS AND/OR BARGES. Rafts or barges for

proper performance of maintenance and repair work on

general repair work should have a flat, open-deck area

waterfront structures than that of the diver. The diver, in

completely covered with planking that is reasonably tight

addition to being certified, should be experienced in

to prevent both accidents to workmen and the loss of

construction and familiar with construction tools and

tools and equipment. The rafts can be supported on

materials. The diver must also be able to report clearly

logs or pontoons. The structures should be rigid enough

and in exact detail underwater conditions (see Appendix

to withstand considerable shock. The raft should be

A).

equipped with well-secured cleats or other means for

1-10

securing lines. Rafts should be fitted with handrails or

posts less than 4 inches by 4 inches should be used for

lifelines on the sides that are not adjacent to the work.

a scaffold, and they should be securely cross-braced.

Deck planking should be kept in repair by plugging any

Convenient access from the ground and from one level

holes and replacing broken or cracked planks. Rafts

to another should be provided by ladders or stairs that

with steel pontoons and framework should be kept

are rigidly secured. All platform levels should have well-

painted to prevent deterioration and should have

supported life rails. On the land side, supports must be

adequate fendering systems.

placed on firm ground, preferably in such a manner that

they can be wedged up or raised if necessary. If

1.7.3 SCAFFOLDS. All scaffolding shall conform to all

vehicles will pass adjacent to or near the scaffolding,

military and ASSHO safety regulations.

substantial barricades should be placed at least 3 feet

from the supports of the scaffold.

1.7.3.1 Wood Scaffolds. Wood scaffolds should be

built to suit the particular work that is to be done from

Fire extinguishers of adequate size shall be

them. They should be rigid and completely stable in

stationed near wood scaffolds to conform with fire

themselves, even when not secured to a structure. No

regulations.

less than two 10-inch-wide planks of 2-inch nominal

thickness should be used as the platform. The

1.7.3.2 Pipe Scaffolds. Pipe scaffolds should be free

unsupported span shall not exceed 10 feet. All planks

of any bent, dented, or otherwise defective members.

used for scaffold platforms should be tested

Every connector of each tier must be made tight before

immediately prior to the installation of the framework. If

the next tier is installed. Joints and connectors in pipe

no other means of testing is available, each plank

scaffolds must be tightly bolted. Scaffold supports

should be placed flat and supported at each end by a

should be maintained in a vertical position.

block 12 inches high. The plank should then be loaded

at its midpoint with twice the anticipated load on the

1.7.3.3 Hung Scaffolds. Platform planking and life rails

scaffold, and the load left on for at least 5 minutes. If

for hung scaffolds should be similar to those for built-up

visible or audible failure occurs, or if the plank remains

scaffolds. The rope or line used should be of more than

deformed after the load is removed, it should be

ample size and free of defects; it should be secured to

discarded. All scaffold planks should be free of large

cleats, bitts, a string piece, or another substantial part of

knots, shakes, splits, checks, or any other visible

the structure. The scaffolds should also be equipped

defects. All scaffold planks should be securely

with a positive mechanical or structural means of

fastened. Any scaffold plank that, by use or accident,

belaying the free end of the rope or line.

becomes broken, cracked, warped, or in any way

defective should be replaced immediately by a sound

1.7.4 LADDERS. All ladders should be made with

plank.

sound, secure rungs notched into, or passing through,

The strength of the scaffold framework should

be more than sufficient for the height of the scaffold. No

1-11

the stringers. Broken or cracked rungs should be

and redriving the sheeting further as excavation

replaced immediately. Ladders should not be painted

progresses

because this could conceal defects.

(3)

Installing breast boards around the sides

of the excavation as it progresses downward.

Wooden ladders shall be treated occasionally

(4)

Driving soldier beams and placing breast

with clear linseed oil to prevent the wood from drying

boards between them as the excavation progresses.

out. New ladders, especially those with hardwood

rungs, should be dipped in a 5% pentachlorophenol

Where excavations are necessary beneath the

solution for 3 minutes to deter rotting. If dipping is not

water table, it may be necessary to dewater the site to

possible, the solution should be brushed or sprayed on.

permit working in the dry. In such instances the major

Linseed oil need not be applied when the latter

criteria to meet are those dealing with loss of stability of

treatment has been used.

the bottom or sides of the excavation and removal of

the water (see References 1-18 through 1-20).

1.7.5 EXCAVATIONS. Excavations for repair work are

normally required for access to underground parts of a

In some cases it may be necessary to stabilize

structure. The safety of the structure during excavation

the soil prior to excavation by using, for example,

is of prime consideration. The excavation should be

electroosmosis for fine-grained soils, or freezing or

made so that the surrounding ground does not lose its

grouting to stabilize the coarser soils (see Reference 1-

own stability or such support as it may be giving to the

18).

adjacent structure. This is accomplished by:

(1)

Removing material in a manner so that a

Necessary measures should be taken and

stable, sloping bank is created around the sides of the

careful observations made to be sure mud, silt, water

excavation.

slurry, and other excavation materials do not undermine

(2)

Driving vertical wood, concrete, or steel

adjacent roads, piers, fills, tracks, and facilities.

sheeting around the sides of the area to be excavated,

SECTION 8. SAFETY

1.8.1 INSTRUCTIONS. Safety precautions and safe

conditions at the site of the work and ASSHO

maintenance practices are covered in detail in the

regulations. Safety lines should be rigged with as little

following:

slack as possible. If the slack is more than two or three

feet, a workman could be injured by even this short fall.

(1)

Army EM 385-1-1 [1-21]

Always use a safety belt, never a loop of rope around a

(2)

Navy NAVFAC 5100.1 1 A [1-22]

man's body. Insist on workmen using hard hats, unless

(3)

Air Force AFM 127-101 [1-23]

they are clearly unnecessary, and require them to wear

safety glasses when chipping, grinding, or sandblasting.

1.8.2 PERSONAL PROTECTION. Workmen in

Safety shoes and other types of protective clothing are

hazardous locations should wear life belts or safety belts

(or both) attached to safety 1 lines according to the

1-12

frequently necessary and should be used. A respirator

normally provided in berthing areas to cushion the

should be available for use should the need arise.

impact of ships when docking. In some cases, it may be

economical to provide dolphins for additional protection

1.8.3 BARRICADES AND SAFETY LINES. All unsafe

to waterfront structures. All special problems of