it is a new command, the state of the task is changed to S1 and the status of the task is

changed to indicate that it is executing.

Pick and Place Next Beam

S0 New Command

S1 Hold – Status=Executing

S1 Conditions Good to Move to Pre-Pick Pose

S2 Move to Pre-Pick Pose

S1 Timed out

S0 Hold – Status=Error

S2 Conditions Good to Move to Pick Pose

S3 Move to Pick Pose

S3 Conditions Good to Grasp

S4 Grasp Beam

S4 Conditions Good to Pre-Load Crane

S5 Pre-Load Crane

S5 Conditions Good to Move to Pre-Place Pose

S6 Move to Pre-Place Pose

S6 Conditions Good to Move to Place Pose

S7 Move to Place Pose

S7 Conditions Good to Unload Crane

S8 Unload Crane

S8 Conditions Good to Release

S9 Release Beam

S9 Conditions Good to Move to Post Place Pose

S10 Move to Post Place Pose

S10 At Post Place Pose

S0 Hold - Status=Done

Table 1. State table for the pick and place next beam task.

The next time the above state table is checked (i.e., during the next execution cycle of its

corresponding control module) the new state of the task is S1, and the conditions that must

be met are whether it is acceptable to move RoboCrane to the beam’s pre-pick pose, or

whether enough time has elapsed that something must be wrong. There may be one or more

sub-conditions that must be satisfied in order to determine whether it is acceptable to

proceed, but these can be aggregated into one description in the state table. If the conditions

are met, the state of the task is changed to S2 and the command to move to the pre-pick pose

is sent to a lower-level task. If time has expired, the state of the task is changed to S0 and an

error is reported. Each lower level task that receives an output command reports its status

back to the higher level task that issued the command until it finishes executing or

18

Parallel Manipulators, Towards New Applications

encounters an error. This process continues until all of the commands in the state table have

been executed, at which point the pick and place next beam task is considered completed

and the state of the table is reset to S0. For brevity, only a single timeout condition is shown

in Table 1. In practice, numerous checks of this sort are made throughout the state table.

Once the state tables for all of the tasks identified through the task decomposition process

are completed they are organized into control modules as described next and implemented

in software following the RCS guidelines.

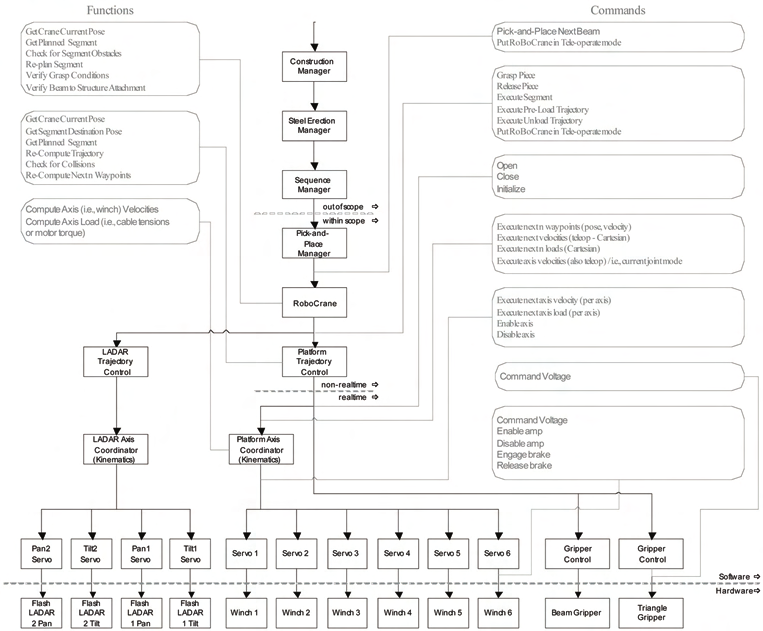

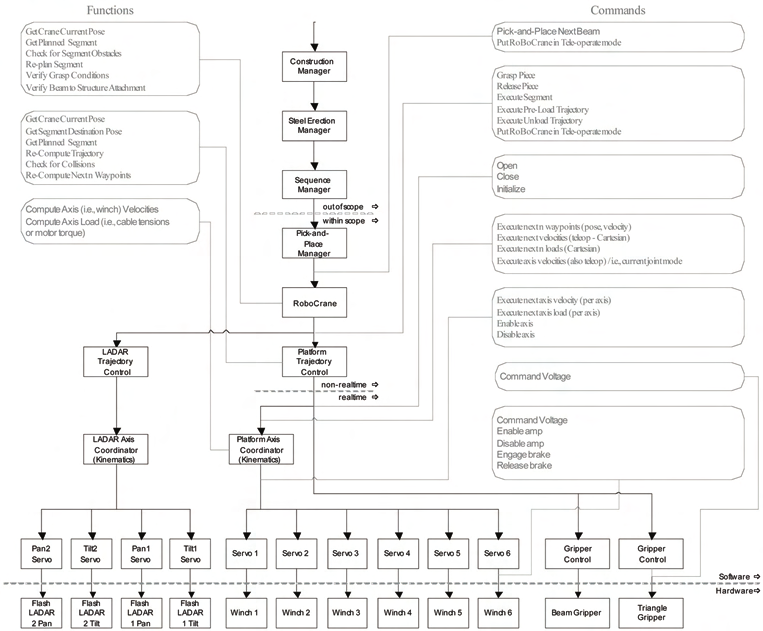

Control Modules: As indicated in the prior RCS description, the commands in the task tree

diagram of Figure 11 are organized into multiple levels. Each level’s tasks may be grouped

together into one or more modules responsible for coordinating and executing the tasks

within it. Some of the critical modules (such as the servo algorithms) run as real-time

processes within the operating system, while other less critical modules (such as long term

path planning) run as non-deterministic processes.

Figure 12 shows the control architecture for the RoboCrane controller. The four levels above

the software/hardware demarcation line in Figure 12 correspond to the four levels of

Figure 11. The tasks have been grouped into the control modules shown. For example, the

bottom level tasks of Figure 11 are grouped into the six “Servo” modules in Figure 12.

Fig. 12. RoboCrane controller architecture diagram.

Control of Cable Robots for Construction Applications

19

Each of these modules are responsible for executing a servo algorithm which accepts the

actual and desired positions (or velocity) of a winch motor as inputs and calculates a

command voltage which maintains the desired position (or velocity). An alternate

configuration would be to group the six servo modules into one.

Figure 12 also shows that the RoboCrane controller is part of a larger control architecture

which includes four higher-level modules. For example, at the level above the RoboCrane

controller would be a Pick-and-Place Manager that would actually command RoboCrane to

perform the pick-and-place operation. The commands sent down by each module to a

lower-level module are shown in the light gray boxes on the right. Some of the functions (or

non-physical tasks) that each module performs are also shown in the light gray boxes on the

left. The control modules above the Pick-and-Place Manager are also included in the figure.

Finally, Figure 12 also includes modules for controlling the 3D imaging systems. These

modules are responsible for coordinating the sensor orientations with the RoboCrane

platform’s motion in order to maintain a desired part of RoboCrane’s environment within

the combined sensors’ field of view.

6. Conclusion

This chapter presented new research developments at NIST in control algorithms and

controller design for parallel robots applied to Construction applications. In particular, this

research focused on the NIST RoboCrane platform for automated placement of construction

components. This work was the first to demonstrate the use of a laser-based site

measurement system for 6 degree-of-freedom tracking of a robotic crane, and presented new

methods for incorporating pose estimation errors in a compensation transform for the NIST

GoMotion controller. Finally, this work presented task decomposition approaches for

analyzing and automating construction crane operations based on a NIST 4D/RCS

approach.

7. References

Albus, J., Huang, H., Messina, E., Murphy, K., Juberts, M., Lacaze, A., Balakirsky, S.,

Shneier, M., Hong, T., & Scott, H. (2002). 4D/RCS Version 2.0: A Reference Model

Architecture for Unmanned Vehicle Systems. National Institute of Standards and

Technology, Gaithersburg, MD, NISTIR 6912.

Albus, J.S., Bostelman, R.V., & Dagalakis, N.G. (1992). The NIST ROBOCRANE, A Robot

Crane. Journal of Robotic Systems, July.

Barbera, T., Albus, J., Messina, E., Schlenoff, C., & Horst, J. (2004). How task analysis can be

used to derive and organize the knowledge for the control of autonomous vehicles.

Robotics and Autonomous Systems 49(1-2), 67-78.

Bostelman, R., Jacoff, A., Dagalakis, N., & Albus, J. (1996). RCS-Based RoboCrane

Integration. Proc. Intelligent Systems: A Semiotic Perspective, Gaithersburg, MD, Oct,

20-23.

Bostelman, R., Shackleford, W., Proctor, F., Albus, J., & Lytle, A. (2002). The Flying Carpet:

A Tool to Improve Ship Repair Efficiency. American Society of Naval Engineers

Symposium, Bremerton, WA, Sept, 10-12.

20

Parallel Manipulators, Towards New Applications

Gazi, V. (2001). The RCS Handbook: Tools for Real-time Control Systems Software

Development. Wiley.

Tsai, L.W. (1999). Robot Analysis: The Mechanics of Serial and Parallel Manipulators. Wiley-

Interscience.

2

Dynamic Parameter Identification for

Parallel Manipulators

Vicente Mata1, Nidal Farhat1, Miguel Díaz-Rodríguez2,

Ángel Valera3 and Álvaro Page4,

Universidad Politécnica de Valencia, Departamento de Mecánica y Materiales Valencia1,

Universidad de los Andes, Facultad de Ingeniería,

Departamento de Tecnología y Diseño Mérida2,

Universidad Politécnica de Valencia, Departamento de Ingeniería

de Sistemas y Automática Valencia3,

Universidad Politécnica de Valencia, Departamento de Física Aplicada Valencia4,

España1,3,4,

Venezuela2

1. Introduction

The information provided by robot manufacturers regarding the dynamic parameters of

robotic systems (the inertial properties of the links and friction parameters at the kinematic

joints) is limited and even nonexistent. For instance, friction parameters are generally not

provided. Thus, it is necessary to develop efficient procedures for their measurement. The

direct measurement of these parameters is not practical since it would imply disassembling

the robot. On the other hand, obtaining these parameters from the CAD models has the

disadvantage that some parts can not be modeled in full detail and parameters that depend

on operational conditions, like friction, can not be determined. For these reasons, parameters

identification has turned out to be a widely accepted technique for determining the dynamic

parameters. This chapter provides an overview of parameters identification processes

applied to parallel manipulators. Practical implementation issues are also considered. In

addition, an approach that considers the identification problem as a nonlinear constrained

optimization problem is presented. Moreover, an evaluation of the accuracy of the solution

of parameters is also addressed.

The importance of inertial and friction parameters lies in their application in most of the

recent literature for advanced model-based control algorithms. The accuracy of dynamic

parameters plays an important role in the precision, performance, stability and robustness of

these control algorithms (Khalil & Dombre, 2002). On the other hand, they are important in

dynamic simulation. It is known that the validation of the direct dynamic problem depends

considerably on the precision of the dynamic parameters of the mechanical system. An

accurately modeled robot permits the substitution of the real mechanical system by a virtual

one thus avoiding the expensive experimental tests used to adjust the operational

parameters for this system (Hiller et al., 2002). Additionally, another important field in

which accurate knowledge of the dynamic parameters is needed is in path planning

22

Parallel Manipulators, Towards New Applications

algorithms that take into account robot dynamics. The predicted forces depend greatly on

the accuracy of the estimated inertial and friction parameters. Hence, inaccurate estimates of

the dynamic parameters may lead to an overloaded robot (dynamically or statically), which

is the case in approximately 50% of industrial robots (Swevers et al., 2002).

Initially, dynamic parameter identification procedures for estimating the dynamic

parameters of open loop mechanical structures were developed in the middles eighties

(Khosla & Kanade, 1985; Atkeson et al., 1986; Olsen & Bekey, 1986; Gautier & Khalil, 1988).

Since then, they have been widely used and several contributions to serial robot dynamics

application control and simulation have been made.

Identification procedures can be classified into two main groups: indirect and direct

approaches. On the one hand, indirect procedures act sequentially in several stops. In each

step, parameters of a different nature (basically friction and some inertial terms) are

identified by means of specifically designed experiments. On the other hand, in the direct

approach, all the parameters are identified in the same stage. A detailed comparison

between the direct and the indirect approaches, applied to a PUMA industrial robot, can be

found in Benimeli et al. (2006). The indirect approach has the disadvantage that errors due

to the noise in the measured data are being accumulated throughout the different stages

(Khalil & Dombre, 2002). Moreover, it is difficult to maintain the working conditions

constant not only throughout these stages, but also within the same one.

For parallel manipulators, the direct approach has been applied (Renaud et al., 1993;

Guegan et al., 2003; Farhat et al., 2008). Meanwhile, the indirect approach has been proposed

(Grotjahn et al., 2004; Abdellatif et al., 2007). However, apart from error accumulation in

each step, the separation of the parameters of a different nature is not straightforward as for

open chain manipulators. Due to the fact that the direct approach allows parameters

identification in one single experiment, removing the accumulation of error between steps,

this chapter will be focus on the direct approach applied to parallel manipulators.

The first part of the chapter deals with conventional direct dynamic parameters

identification processes. Thus, the dynamic model, suitable for identification purposes, is

developed in its linear form with respect to the dynamic parameters. Due to the fact that the

number of parameters is usually greater than the dimension of the equations of motion, an

overdetermined system is developed. This overdetermined system is rank deficient,

therefore it has to be reduced to another equivalent system that only contains independent

columns. These columns correspond to a subset of parameters called the base parameters.

Reduction process can be held symbolically (Khalil & Bennis, 1995) or numerically (Gautier,

1991). For experiment design and in order to reduce the sensitivity of the system to the noise

signal, procedures have been developed for the trajectories to be executed by the

manipulator (Gautier & Khalil, 1992; Swevers et al., 1997). Finally, the dynamic system in its

reduced matrix form is solved for the base parameters using the Least Square Method

(LSM).

The parameters dynamic identification procedure outlined in the previous paragraph has

two main disadvantages: firstly, results could contain non-physically feasible parameters

and secondly, it is also limited to linear friction models. Non-physical feasibility can be

detected by obtaining a base parameters solution that does not have any physical

interpretation when compared with corresponding combinations of the inertial parameters;

masses lower than zero or non positive-definite local inertial matrices (Yoshida & Khalil,

2000). This issue not only affects the stability of some of the advanced model-based control

algorithms, but is also crucial in the dynamic simulation tasks.

Dynamic Parameter Identification for Parallel Manipulators

23

The second part of the chapter will focus on two identification procedures. First, a

procedure based on the parameters identification formulated as a nonlinear constrained

optimization problem is reviewed. This approach allows not only the implementation of

nonlinear friction models to model friction phenomenon at robot joints, but also the

consideration of constraint equations in order to ensure the physical feasibility of the

identified parameters. The second procedure is established upon the accuracy of the

parameter solution, which is called here the identifiability of the parameters . Experiments

will be held on a class of parallel manipulator. The main conclusions and further research

concerning parameters identification for parallel manipulators are presented at the end.

2. Dynamic model

The starting point of the identification process depends on obtaining the dynamic model of

the mechanical structure in its linear form with respect to the inertial and friction

parameters. For this purpose, the dynamic model can be developed basically by two

methods (Kozlowski, 1998); the integral and the differential methods. The integral method is

derived from the energy equation and requires measurements of positions, velocities and

applied forces on the actuated joints. Measurements of accelerations are not required. This

method has been applied on serial manipulators (Gautier & Khalil, 1988; Sheu & Walker,

1989; Khalil et al., 1990; Sheu & Walker, 1991) and extended for parallel manipulators

(Bhattacharya et al., 1997). Olsen and others also used the integral method (Olsen &

Petersen, 2001; Olsen et al., 2002) where they proposed the use of the maximum likelihood

method instead of the conventional Least Squares Method (LSM) in the identification

process.

On the other hand, the differential method takes the advantage of the equations of motion as

a base in the development of the identification process algorithms. As a result, acceleration

appears explicitly and needs to be measured. It is known that the equations of motion can be

constructed implementing various dynamic principles. Models suitable for the identification

process have been developed by means of; the Newton-Euler formulation (Luh et al., 1980;

Atkeson et al., 1986; Olsen & Bekey, 1986; Khosla, 1989), the Lagrange formulation (Ha et al.,

1989; Sheu & Walker, 1991), Jourdain’s principle of Virtual Power (Grotjahn et al., 2004),

Gibbs-Appell equations of motion (Benimeli et al., 2003) and recently (Hardeman et al.,

2006), a finite element based approach along with Jourdain’s principle of Virtual Power was

used to develop an automatic generation of the dynamic models for identification.

In order to study the advantages/disadvantages of the integral and differential methods, a

comparison was carried out. The experiments were held considering a two degrees of

freedom serial manipulator (Prufer et al., 1994). From the results, they concluded that the

differential method has advantages over the integral one. Thus, the differential model is

used here for parameters identification of parallel manipulators.

2.1 Rigid body model

The equation of motion that describes the dynamic behavior of an open chain manipulator

can be obtained by means of Gibbs-Appell equations of motion. For a serial robot (Mata et

al., 2002), the rigid body dynamic model can be written as follows,

24

Parallel Manipulators, Towards New Applications

n ⎧⎛

T

T

⎪ ∂ i ω

⎫

n ⎡

i

⎤

⎞

⎛ r

i

i

i

i

i

i

⎪

∂

⎞

τ =

I

( I

)

m

r

(1)

k

∑ ⎜⎨

⎟ ⋅ ⎡

⋅ ω + ω ×

⋅ ω ⎤

G

i

i

G

i

⎬ +

⎢

G

i

i

i

∑ ⎜

i ⎟ ⋅

⋅

⎥

⎣

⎦

i k

∂ q

q

k

i k ⎢⎜ ∂

⎟

i

Gi

=

⎝

⎪

⎠

=

⎥

⎩

⎪⎭

⎝

k ⎠

⎣

⎦

where τ and q are the generalized forces and accelerations of the joint k, respectively, iω

k

k

i

is the angular acceleration, and i r is the acceleration of the center of gravity, m is the

Gi

i

mass and iI is the inertial tensor of the center of gravity, and the superscript/subscript (i)

Gi

stands for the link number. All of them expressed with respect to the ith local reference

frame. The Denavit-Hartenberg modified convention has been considered for modeling the

system and i = k..n indicates the sum over all links above joint k, including itself.

For dynamic parameters identification, a linear form with respect to dynamic parameters is

necessary. To this end (Atkeson et al., 1986), the linear acceleration of the center of gravity of

the ith body is expressed as a function of the linear acceleration of the link coordinate frame

ith. Moreover, the link inertial tensor is also expressed about the link coordinate frame by

means of parallel axis theorem.

In addition, the following notations are introduced. On the one hand, the cross product

a × b is expressed using the skew symmetric matrix a . Thus, a × b = a ⋅ b where,

⎛ 0

−a

a ⎞

z

y

⎜

⎟

T

a = a

0

−

⎜

a and b = ⎡b

b

b ⎤

z

x ⎟

⎣ x

y

z ⎦

(2)

⎜ a

a

0 ⎟

−

⎝

y

x

⎠

On the other hand, B ⋅ a = â ⋅ B where,

⎛a

a

a

0

0

0 ⎞

x

y

z

⎜

⎟

T

â = ⎜ 0 a

0 a

a

0 and B = ⎡B

B

B

B

B

B ⎤

x

y

z

⎟

⎣ xx

xy

xz

yy

yz

zz ⎦

(3)

⎜ 0 0 a

0 a

a ⎟

⎝

x

y

z ⎠

By doing the above mentioned, upon substituting (2)-(3) in (1) and using some vector

identities, the dynamic model linear with respect to dynamic parameters can be written as

(Mata et al., 2005),

⎧

n

k T

z ⋅ ∑ k

i

R

ηˆ ⋅ i I +

⎪

i

i

i

i

i

i

r

r

m r

r

r

m

k : R

k

i ⎣ i

i

(

η −

OkOi

i

Oi )

⎫

⎡

⋅

+

⋅

⎤

i

OiGi

OkOi

Oi

i ⎦

⎪

⎪

i k

⎪

=

τ =

(4)

k

⎨

⎬

⎪

z ∑n

k T

k R (

i

i

i

m

r

m r

k : P

k

i

i

Oi

i

i

Oi ,Gi )

⎪

⋅

⋅

⋅

+ η ⋅

⎪

⎪

⎩

i =k

⎭

where i ˆη = ( i

i

i

ˆω + ω ˆω y iη = ( i i

i

ω ω + ω .

i

i

i