Preface

V

1. Control of Cable Robots for Construction Applications

001

Alan Lytle, Fred Proctor and Kamel Saidi

2. Dynamic Parameter Identification for Parallel Manipulators

021

Vicente Mata, Nidal Farhat, Miguel Díaz-Rodríguez,

Ángel Valera and Álvaro Page

3. Quantifying and Optimizing Failure Tolerance of a Class of Parallel Manipu- 045

lators

Chinmay S. Ukidve, John E. McInroy and Farhad Jafari

4. Dynamic Model of a 6-dof Parallel Manipulator Using the Generalized

069

Momentum Approach

António M. Lopes and Fernando Almeida

5. Redundant Actuation of Parallel Manipulators

087

Andreas Müller

6. Wrench Capabilities of Planar Parallel Manipulators and their Effects Under 109

Redundancy

Flavio Firmani, Scott B. Nokleby, Ronald P. Podhorodeski and Alp Zibil

7. Robust, Fast and Accurate Solution of the Direct Position Analysis of

133

Parallel Manipulators by Using Extra-Sensors

Rocco Vertechy and Vincenzo Parenti-Castelli

8. Kinematic Modeling, Linearization and First-Order Error Analysis

155

Andreas Pott and Manfred Hiller

9. Certified Solving and Synthesis on Modeling of the Kinematics. Problems

175

of Gough-Type Parallel Manipulators with an Exact Algebraic Method

Luc Rolland

10. Advanced Synthesis of the DELTA Parallel Robot for a Specified Works-

207

pace

M.A. Laribi, L. Romdhane and S. Zeghloul

VIII

11. Size-adapted Parallel and Hybrid Parallel Robots for Sensor Guided Micro 225

Assembly

Kerstin Schöttler, Annika Raatz and Jürgen Hesselbach

12. Dynamics of Hexapods with Fixed-Length Legs

245

Rosario Sinatra and Fengfeng Xi

13. Cartesian Parallel Manipulator Modeling, Control and Simulation

269

Ayssam Elkady, Galal Elkobrosy, Sarwat Hanna and Tarek Sobh

14. Optimal Design of Parallel Kinematics Machines with 2 Degrees of Free-

295

dom

Sergiu-Dan Stan, Vistrian Maties and Radu Balan

15. The Analysis and Application of Parallel Manipulator for Active Reflector

321

of FAST

Xiao-qiang Tang and Peng Huang

16. A Reconfigurable Mobile Robots System Based on Parallel Mechanism

347

Wei Wang, Houxiang Zhang, Guanghua Zong and Zhicheng Deng

17. Hybrid Parallel Robot for the Assembling of ITER

363

Huapeng Wu, Heikki Handroos and Pekka Pessi

18. Architecture Design and Optimization of an On-the-Fly Reconfigurable

379

Parallel Robot

Allan Daniel Finistauri, Fengfeng (Jeff) Xi and Brian Petz

19. A Novel 4-DOF Parallel Manipulator H4

405

Jinbo Wu and Zhouping Yin

20. Human Hand as a Parallel Manipulator

449

Vladimir M. Zatsiorsky ad Mark L. Latash

21. Mobility of Spatial Parallel Manipulators

467

Jing-Shan Zhao, Fulei Chu and Zhi-Jing Feng

22. Feasible Human-Spine Motion Simulators Based on Parallel Manipulators 497

Si-Jun Zhu, Zhen Huang and Ming-Yang Zhao

1

Control of Cable Robots for

Construction Applications

Alan Lytle, Fred Proctor and Kamel Saidi

National Institute of Standards and Technology

United States of America

1. Introduction

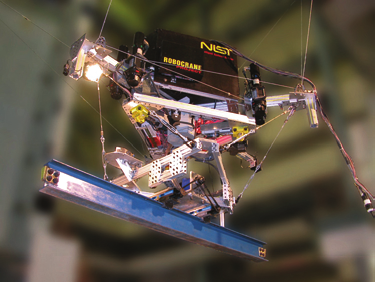

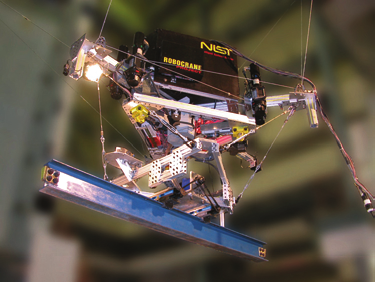

The Construction Metrology and Automation Group at the National Institute of Standards

and Technology (NIST) is conducting research to provide standards, methodologies, and

performance metrics that will assist the development of advanced systems to automate

construction tasks. This research includes crane automation, advanced site metrology

systems, laser-based 3D imaging, calibrated camera networks, construction object

identification and tracking, and sensor integration and process control from Building

Information Models. The NIST RoboCrane has factored into much of this research both as a

robotics test platform and a sensor/target positioning apparatus. This chapter provides a

brief review of the RoboCrane platform, an explanation of control algorithms including the

NIST GoMotion controller, and a discussion of crane task decomposition using the Four

Dimensional/Real-time Control System approach.

1.1 The NIST RoboCrane

RoboCrane was first developed by the NIST Manufacturing Engineering Laboratory’s

(MEL) Intelligent Systems Division (ISD) in the late 1980s as part of a Defense Advanced

Research Project Agency (DARPA) contract to stabilize crane loads (Albus et al., 1992). The

basic RoboCrane is a parallel kinematic machine actuated through a cable support system.

The suspended moveable platform is kinematically constrained by maintaining tension due

to gravity in all six support cables. The support cables terminate in pairs at three vertices

attached to an overhead support. This arrangement provides enhanced load stability over

beyond traditional lift systems and improved control of the position and orientation (pose)

of the load. The suspended moveable platform and the overhead support typically form two

opposing equilateral triangles, and are often referred to as the “lower triangle” and “upper

triangle,” respectively.

The version of RoboCrane used in this research is the Tetrahedral Robotic Apparatus

(TETRA). In the TETRA configuration, all winches, amplifiers, and motor controllers are

located on the moveable platform as opposed to the support structure. The upper triangle

only provides the three tie points for the cables, allowing the device to be retrofitted to

existing overhead lift mechanisms. Although the TETRA configuration is presented in this

chapter, the control algorithms and the Four Dimensional/Real-time Control System

(4D/RCS), for 3D + time/Real-time Control System, task decomposition are adaptable to

2

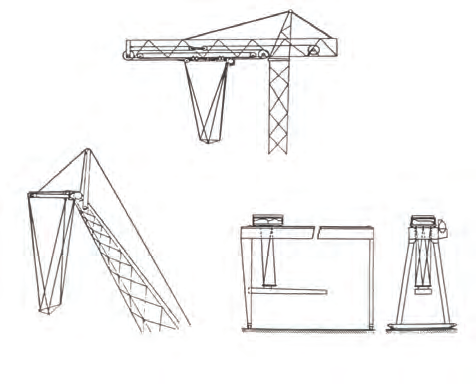

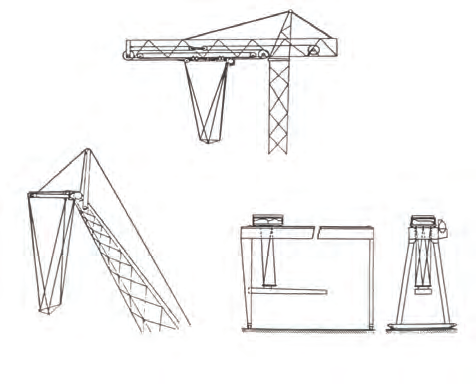

Parallel Manipulators, Towards New Applications

many different crane configurations. The functional RoboCrane design can be extended and

adapted for specialized applications including manufacturing, construction, hazardous

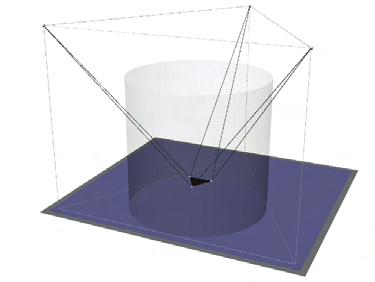

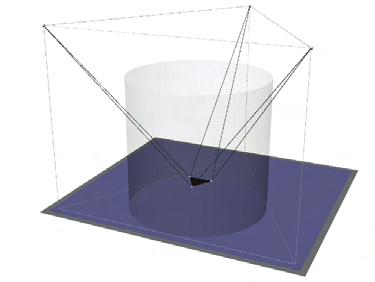

waste remediation, aircraft paint stripping, and shipbuilding. Figure 1 depicts the

RoboCrane TETRA configuration (a) and the representative work volume (b). Figure 2

shows additional retrofit configurations of the RoboCrane platform, and Figure 3 shows

implementations for shipbuilding (Bostelman et al., 2002) and aircraft maintenance.

(a) (b)

Fig. 1. RoboCrane – TETRA configuration (a); Rendering of the RoboCrane environment.

The shaded cylinder represents the nominal work volume (b).

Fig. 2. Illustrations of RoboCrane in possible retrofitted configurations: Tower Crane (top),

Boom Crane (lower left) and Gantry Bridge Crane (lower right).

1.2 Motivation for current research

Productivity gains in the U.S. construction sector have not kept pace with other industrial

sectors such as manufacturing and transportation. These other industries have realized their

productivity advances primarily through the integration of information, communication,

Control of Cable Robots for Construction Applications

3

automation, and sensing technologies. The U.S. construction industry lags these other

sectors in developing and adopting these critical, productivity-enhancing technologies.

Leading industry groups, such as the Construction Industry Institute (CII), Construction

Users Roundtable (CURT) and FIATECH, have identified the critical need for fully

integrating and automating construction processes.

Robust field-automation on dynamic and cluttered construction sites will require advanced

capabilities in construction equipment automation, site metrology, 3D imaging, construction

object identification and tracking, data exchange, site status visualization, and design data

integration for autonomous system behavior planning. The NIST Construction Metrology

and Automation Group (CMAG) is conducting research to provide standards,

methodologies, and performance metrics that will assist the development, integration, and

evaluation of these technologies. Of particular interest are new technologies and capabilities

for automated placement of construction components.

(a) (b)

Fig. 3. The NIST Flying Carpet – a platform for ship access in drydocks (a) and the NIST

Aircraft Maintenance Project (AMP) – a platform for aircraft access in hangars (b).

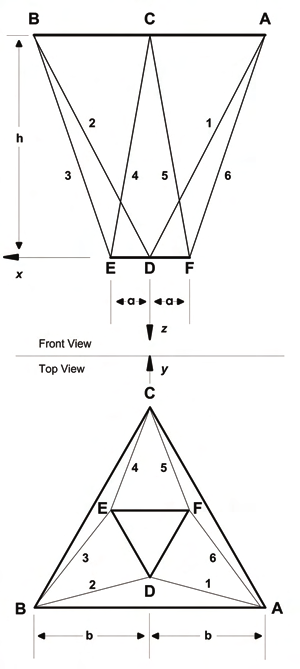

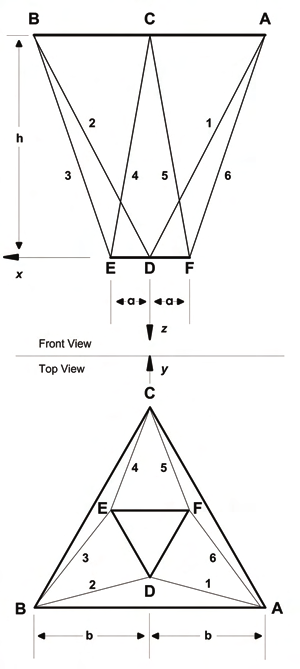

2. RoboCrane kinematics

From (Albus et al., 1992), given an initial condition where the overhead support and the

suspended platforms are represented by parallel, equilateral triangles with centers aligned

along the vertical axis Z, (see Figure 4), the positions of the upper triangle with vertices A, B,

and C and lower triangle with vertices D, E, and F are expressed as

⎡

b

−

⎤

⎡

b

⎤

⎡ 0 ⎤

⎢ 1

⎥

⎢ 1

⎥

⎢2

⎥

A = ⎢− b 3⎥ B = ⎢− b 3⎥ C = ⎢ b 3⎥

⎢ 3

⎥

⎢ 3

⎥

⎢3

⎥

⎢

h ⎥

⎢

h ⎥

⎢

h ⎥

−

−

−

⎣

⎦

⎣

⎦

⎣

⎦

(1)

⎡

0

⎤

⎡ a ⎤

⎡ − a ⎤

⎢ 2

⎥

⎢1

⎥

⎢1

⎥

D = ⎢− a 3⎥

E = ⎢ a 3⎥

F = ⎢ a 3⎥

⎢ 3

⎥

⎢3

⎥

⎢3

⎥

⎢

0

⎥

⎢ 0 ⎥

⎢ 0 ⎥

⎣

⎦

⎣

⎦

⎣

⎦

4

Parallel Manipulators, Towards New Applications

With the positions of the vertices of triangles ABC and DEF as described in equations (1),

when the lower platform is moved to a new position and orientation (DÉ´F´) through a

translation of

⎡ u ⎤

x

⎢

U

u ⎥

=

(2)

y

⎢ ⎥

⎢ u ⎥

⎣ z ⎦

and a rotation of

R (γ ,θ ,φ) = R (φ) ⋅ R (θ ) ⋅ R (γ ) (3)

yxz

z

x

y

the cable lengths can be expressed as

⎡

2

⎤

⎡

2

⎤

b

− + aQ

3 − u

− b + aQ

3 − u

⎢

12

x

⎥

⎢

12

3

3

x

⎥

⎢

⎥

⎢

⎥

⎢ 1

2

⎥

⎢ 1

2

L

b 3

aQ

3 u

L

b 3

aQ

3 u ⎥

= −

+

−

= −

+

−

1

22

y

2

22

⎢ 3

3

⎥

⎢ 3

3

y ⎥

⎢

⎥

⎢

⎥

2

2

⎢

h

aQ

3 u

⎥

⎢

h

aQ

3 u

⎥

− +

−

− +

−

32

z

32

⎢

3

⎥

⎢

3

z

⎥

⎣

⎦

⎣

⎦

⎡

1

⎤

⎡

1

⎤

b − aQ − aQ

3 − u

⎢

− aQ − aQ

3 − u

11

12

3

x

⎥

⎢

11

12

x

⎥

⎢

⎥

3

⎢

⎥

⎢ 1

1

⎢ 2

1

L

b 3 aQ

aQ

3 u ⎥

= −

−

−

−

L

b 3 aQ

aQ

3 u ⎥

=

−

−

−

(4)

3

21

22

⎢ 3

3

y ⎥

4

21

22

y

⎢

⎥

⎢

3

3

⎥

⎢

⎥

1

⎢ −

1

h − aQ − aQ

3 − u

⎥

⎢

h aQ

aQ

3 u

⎥

− −

−

−

31

32

⎢⎣

3

z

⎦

31

32

⎥

⎢

3

z

⎥

⎣

⎦

⎡

1

⎤

⎡

1

⎤

aQ − aQ

3 − u

− b + aQ − aQ

3 − u

⎢

11

12

x

⎥

⎢

11

12

3

3

x

⎥

⎢

⎥

⎢

⎥

⎢ 2

1

⎥

⎢ 1

1

L =

b 3 + aQ − aQ

3 − u

L = − b 3 + aQ − aQ

3 − u ⎥

5

21

22

y

6

21

22

⎢ 3

3

⎥

⎢ 3

3

y ⎥

⎢

⎥

⎢

⎥

1

⎢

1

h aQ

aQ

3 u

⎥

− +

−

−

⎢ − h + aQ

aQ

3 u

⎥

−

−

31

32

z

3

⎢

3

⎥

⎣

⎦

1

32

⎢

3

z

⎥

⎣

⎦

where

L = A - ′

D

L = B - ′

D

L = B - ′

E

1

2

3

(5)

L = C - ′

E

L = C - F′ L = A - F′

4

5

6

and Q represents an element in the following rotation matrix:

ij

⎡cos(γ )cos(φ) − sin(γ )sin(θ )sin(φ) −cos(θ )sin(φ) sin(γ )cos(φ) + cos(γ )sin(θ )sin(φ)⎤

⎢

Q

cos(γ )sin(φ) sin(γ )sin(θ )cos(φ)

cos(θ )cos(φ)

sin(γ )sin(φ) cos(γ )sin(θ )cos(φ)⎥

=

−

−

⎢

⎥ (6)

⎢

−sin(γ )cos(θ )

sin(θ )

cos(γ )cos(θ )

⎥

⎣

⎦

Therefore, for any new desired pose of the moving platform described by equations (2) and

(3), the required cable lengths to achieve that pose can be calculated by the inverse

kinematic equations shown in equations (4).

Control of Cable Robots for Construction Applications

5

Fig. 4. Graphical representation of the RoboCrane cable support structure.