E 2

0.409

E

1.0

MGT3 with W L

and LG W

E 2

0.212

E

02

Magnetic Microsensors

13

It is noticed that the NEMI is minimum for W L

, and for smaller values of this ratio.

E

0.5

The decreasing of the channel length causes the increase of NEMI with 40.8 % for a square

structure W L and with 173 % for W 2 L .

E

Conclusions

The magnetotransistors have a lower magnetic sensitivity than the conventional Hall

devices but allow very large signal-to-noise ratios, resulting in a high magnetic induction

resolution. The analysis of the characteristics of two magnetotreansistors structures shows

that the W L 0.5 ratio is theoretically favourable to high performance regarding signal-to-

noise ratio, as well as the noise equivalent magnetic induction

Also substituting the silicon technology by using other materials such as GaAs or InSb with

high carriers mobility values assure higher characteristics of the sensors

The uses of magnetotransistors as magnetic sensors allows for the achieving of some

current-voltage conversion circuits, more efficient that conventional circuits with Hall

plates.

The transducers with integrated microsensors have a high efficiency and the possibilities of

using them ca be extended to some measuring systems of thickness, short distance

movement, level, pressure, linear and revolution speeds.

1.7 System to monitor rolling and pitching angles

The efficient operation of the modern maritime ships requires the existence of some reliable

command, watch and protection systems that permit transmission, processing and

receiving of signals with great speed and reduced errors.

On most of the merchant ships the watch of the rolling and the pitching is done by

conventional instruments as gravitational pendulum. The indication of the specific

parameters is continuous, the adjustment operations are manual and the transmissions of

the information obtained in the measurement process, at distance is not possible.

An automatic and efficient surveillance system ensures the permanent indication of the

inclination degree of the ship , the optic and the sound warning in case of exceeding the

maximum admissible angle and the simple transmission of the information at distance.

1.7.1 Installation for the measurement of the rolling and pitching thatuses

magnetotransistors

The presentation of the transducers

The primary piece of information about the rolling and pitching angle is obtained with the

help of the classical system used on ships, with the difference that at the free end of the

pendulum,a permanent magnet with reduced dimensions is fixed provided with polar parts

shaped like those used in the construction of the magnetoelectric measurement devices. Along

the circle arc described by the free end of the pendulum , there are disposed at equal lengths,

accordingly to the displacements of 1 for the rolling and of 1 30’ for the pitching, twenty

magnetotransistors, ten on one side and ten on the other side of the equilibrium position.

Due to the high inertia moment, the pendulum maintains its vertical position, and actually

during the rolling and pitching the graded scale, fixed on the wall, is the one that moves at

the same time with the ship.

14

Microsensors

The transducer for the indication of the rolling is disposed in a vertical plane, transverse on

the longitudinal axis of the ship, and the one for the pitching in a vertical plane that contains

or is parallel with the longitudinal axis of the ship. In order to simplify the presentation will

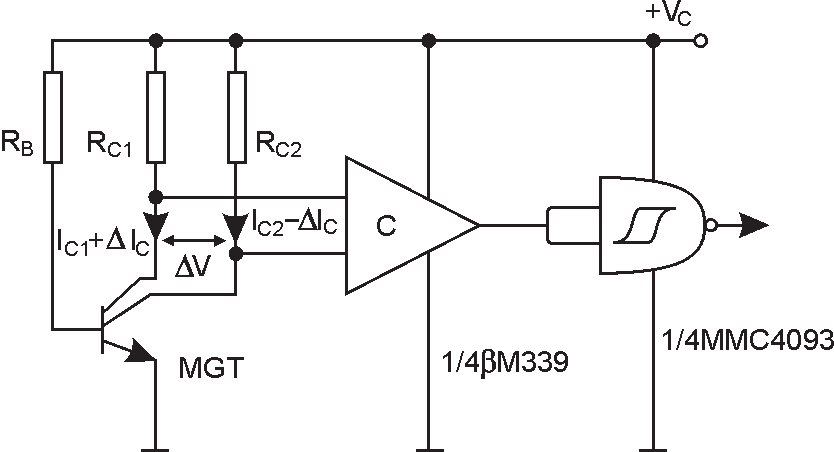

consider that the pendulum is the one that moves in with the graded scale. In figure 1.14 the

principle diagram of the transducer is shown vertical bipolar magnetotransistor with double

collector. In the absence of the magnetic field, the two collector currents are equal and the

output of the comparator is in “DOWN” state (logical level ,,0”). In the presence of a field

of induction B, parallel with the device surface, a lack of poise between the two collector

currents I is produced and at the input of comparator is applied the voltage:

C

V

L W GR I B (1.18)

C

H

/ E

C C

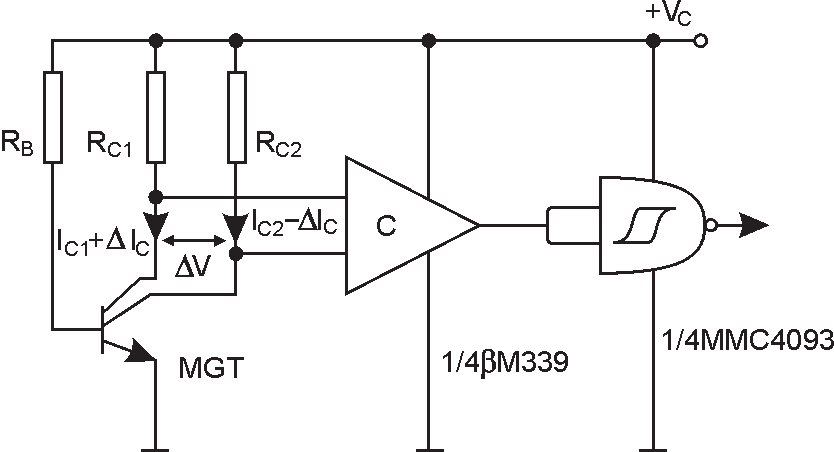

Fig. 1.14. The electric diagram of transducer

This voltage is applied to a comparator with hysteresis, which acts as a commutator. The

existence of the two travel thresholds ensure the immunity of the circuit at noise monostable

made with MMC 4093 ensures the same duration for the transducers generated pulses.

Applied to the comparator C, this voltage changes its state and the output goes on logical

level “1”.

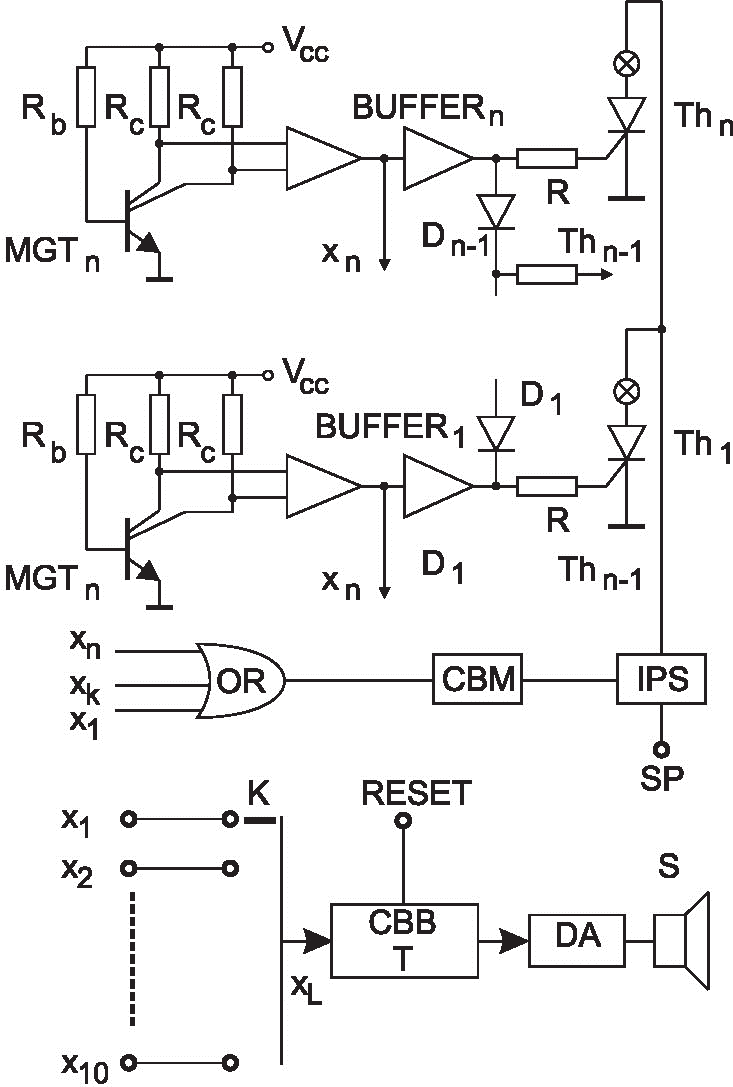

The principle block diagram. The description of working

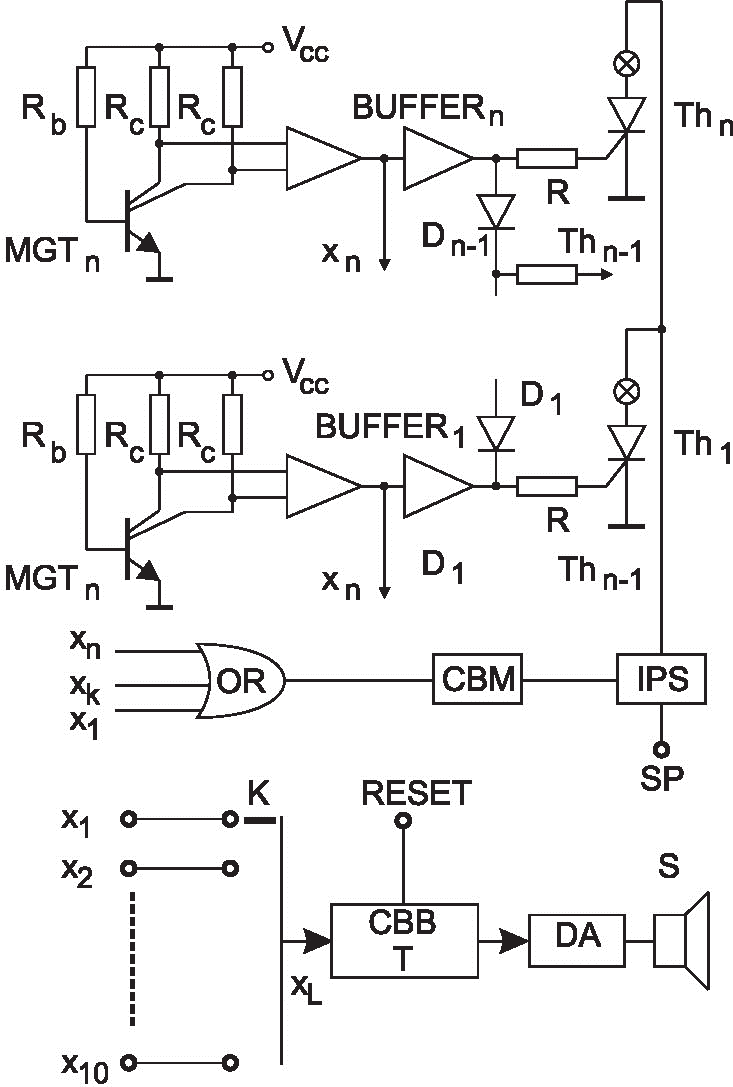

When the ship lists, the permanent magnet of the pendulum will scavenge in turn a number

of magnetotransistors, and the signals from their outputs will determine the tipping of the

comparators. We will thus obtain impulses which are applied through an “OR” circuit at

the CBM input (figure 1.15). This commands the block for the interruption of the power

supply (IPS), achieving the cancellation of the potentials in the thyristors anode for a time

interval of milliseconds.

At the same time the impulses generated by the transducers are transmitted with the help of

separator B1, B2, …, B10 on the thyristors gates, determining their damping. Once the

thyristors are damped, they maintain that state, therefore these are memorizing the last

indicated value, until the power supply is cancelled. So if the rolling or the pitching have

intermediate values ranging between the successive marks of the graded scale , the last

complete measured value remains displayed.

Magnetic Microsensors

15

For a rolling value noted with “K” , all the displays from one to “K” will work in “bright

point” mode, when for the same “K” value of the rolling will be lighted, therefore the

scheme allows the analogical display in bar mode.

Eliminating the diodes D1, D2, …, D9, the display will be in ”bright spot” mode when for

the same value “K” of rolling only the “K” display is lighted.

If the inclination of the ship reaches a limit value L settled beforehand with the help of the

,,K” switch , then the output signal XL (L=1,2,…,10) commands the bistable of T type which

commutes, releasing the sound alarm device.

Fig. 1.15. The diagram of the installation for the measurement of the rolling and pitching

Supposing that the angle of the ship’s list increases, the pendulum overtakes the ,,L’’

position and after it touches a maximum deviation it starts the return run in which it will

pass again through the front of the magneto transistor. The impulse generated by this, will

swing again the bistable and the sound alarm ceases.

An undesirable situation appears when the maximum inclination of the ship has precisely

the pre-established “L” value or it exceeds very little this value. In this case, in the return

16

Microsensors

run of the pendulum a new “XL” impulse, which will swing again the bistable, is no longer

generated and therefore the acoustic alarm is maintained although the inclination angle has

been reduced.

This drawback can be eliminated either by using the “XL-1” output for the bistable command

on the input or by replacing the bistable with one of R-S or J-K type commanded by “XL”

and “XL-1” signals. The “XL” signal establishes the placing in function of the alarming device

and the XL-1” signal the blockage of this device, which permits to obtain a safety hysteresis.

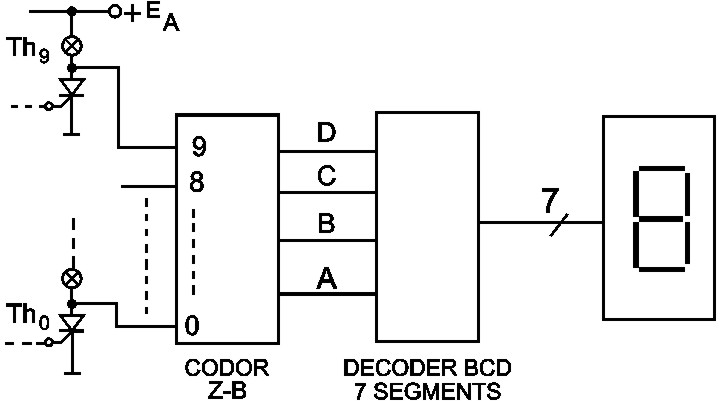

If in the scheme in figure 1.15 the diodes D1, D2, …, D9 are eliminated, then in every

moment a single thyristor will be in conduction, suitable at a certain angle.

The signals in the anodes of the other blocked thyristors will be at the logical level “1” and

only in the anode of the commanded thyristor the signal will have the logical level “0”. This

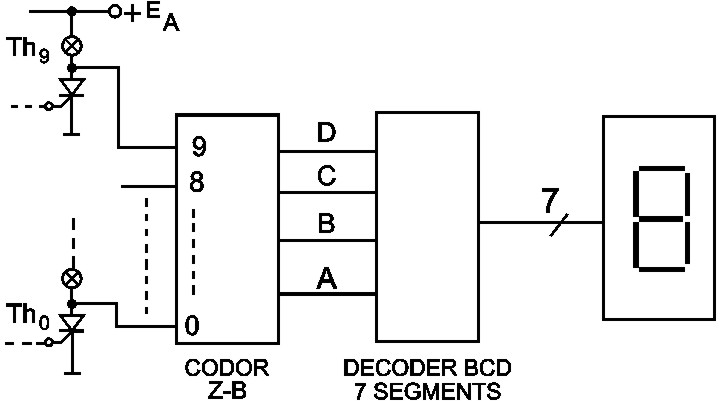

signals are applied to a binary-decimal circuit, at the output of which is obtained the value

of the angle in the binary code. A decoder seven segments which commands a display with

seven segments and permits the digital display of the measured value.(figure 1.16).

The binary-decimal coder can be a matrix of diodes, a matrix of connected gates in a suitable

way, or a specialized circuit like those used in numerical keyboards.

Fig. 1.16. The electrical diagram of the digital display

1.7.2 Installation for the measurement of the rolling and the pitching that uses

phototransistors

The presentation of the transducer

The principle scheme of the photoelectric transducer is shown in figure 1.17. Classical

system on board ships,is used but at the free end of the gravitational pendulum an

electroluminiscent diode (LED) in visible or in infrared is set moves along an arc of circle on

which the phototransistors are placed. The LED pendulum and the phototransistors are

fixed in a box which protects them from the exterior light.

The power supply is ensured from a stabilized source of 12V.

Through one phototransistor, with off–load base / unconnected base and in the absence of

the light the so-called “dark current” will flow between the emitter and the collector.

I I

(1.19)

D

CB 0

where denotes the amplification factor of the transistor and I

is the current generated

CB 0

by the base-collector junction, in the absence of light.

Magnetic Microsensors

17

When the base-collector junction is illuminated, through this an illumination current will

appear ( I and this current is all the intense as the illumination is bigger, and the collector l )

current becomes:

I I

I

(1.20)

C

CB 0 l

Since the phototransistors are blocked in the absence of the illumination, the output voltage

of the collector is practically equal with the value of the power supply ( E) . In the moment

of the illumination the phototransistors are saturated and the collector voltage lowers to

U

value. Therefore the signal given by the transducer is in shape of negative power

CEsat

impulses with the amplitude approximately equal to the value of the power supply

+ED=12V

R

R

D

C

I

I

D

C

LED

Q0

Fig. 1.17. The photoelectric transducer

The principle block diagram. The description of working

Because the measurement of the rolling and the pitching is in fact reduced to the

measurement of an angle, the measurement system is made up of two identical

measurement blocks, one for the rolling and the other for the pitching, with the difference

that the measurement transducer will be placed differently: the one for the rolling on the

transversal axis of the ship and the one for the pitching on the longitudinal ship’s axis.

In figure 1.18 it is presented the block scheme of the measurement system of the inclination

angle of the ship on the longitudinal (transversal) axis of the ship. In this scheme the

following notations have been used: TM -measurement transducer of the rolling (pitching);

CF - formatter circuit; CM-memory cell; IO - optic indicator; CR -resetting circuit; OC -

commanded oscillator; AAF – audio frequency amplifier; SB - supply block; HA - warning

block.

It is noticed that the measurement system is made up “2n+1” identical measurement and

display chains:

-

a chain corresponding to the equilibrium position (zero)

-

“n” chains corresponding to ,,n” number of values of the port inclination angle (stern)

-

“n” chains corresponding to ,,n” number of values of the starboard inclination angle

(bow)

The measurement transducer (TM) supplies the necessary information about the inclination

angle in a discrete way, meaning that the total angle can be measured has been divided into

“2n” sectors (“n” port sectors “n” starboard sectors), and the transducer supplies one

impulse for the output suitable for the inclination angle reached by the ship. The impulse

18

Microsensors

suitable for this angle is processed in the formatter circuit (CF) and it is applied to the

corresponding memory cell (MC), in which the information about the inclination angle of

the ship is kept. This information is displayed by the optic indicator (IO) corresponding the

same sector, until the ship, in her movement, reaches the same inclination angle, but moving

in reverse direction. The measurement transducer generates at the same output a new

impulse that wipes up the information from the memory cell and at the same time the

display of the optic indicator. In this way, the measurement transducer supplies two

impulses for every inclination angle of the ship, except for the maximum inclination angle,

which is pre-established. In case of maximum inclination, the transducer produces a single

impulse that is memorized and displayed until the ship, after she reaches the maximum

inclination angle in the opposite direction, returns to the equilibrium position. In the passing

moment through the equilibrium position, the impulse from the CF out put wipes up, with

the help of a reset circuit (CR), the information from all the memory cells and therefore from

the cells corresponding to the maximum angles for the two inclination ways of the ship.

From now on the working of the system is continued from the equilibrium position.

CF

CM

IO

2n

2n

2n

n

CF

CM

IO

21

21

21

2

1 K

OC

AAF

TM

CF

CM

IO

0

0

0

CF

CM

IO

11

11

11

CF

CM

IO

12V

1n

1n

1n

BA

220V, 50Hz

16V

CR

Fig. 1.18. The block diagram of the measurement system based on the phototransistors

Conclusions

The use of another transducer type for the measurement of the rolling and the pitching,

namely the classic solution with the transducers in Gray code, would have reduced the

number of the components. With such a transducer, using eight pairs of LED

phototransistors a measurement accuracy of the angle, better with 1, could have been

obtained. Besides, this system allows the long distance transmission of the information, but

the solution would have required a sophisticated electronic part, the major difficulty being

the precise construction achievement of the Gray transducer in eight bits.

The block scheme also contains a sound warning system, which is triggered at a maximum

inclination angle pre-established with the help of “K” switch. Once this switch fixed on the

desired position, the logical level from the output of the memory cell corresponding to the

chosen angle, it will command and release the sound warning system.

Magnetic Microsensors

19

This is made up of a command oscillator (OC), an audio frequency amplifier (AAF) and a

warning horn (HA). The command signal of the sound warning system is taken over from

the input of the optic indicator and not from its output, although it would have been easier

to achieve this, out of safety operation reasons. The probability of the memory cell to go out

of order is less than that of the optical indicator, moreover, if the optical indicator goes out

of order that doesn’t imply that the sound warning system gets inoperative.

2. Introduction

The possibility of modelling the channel depth by means of the external supply voltage and

low value of area carrier density suggests the possibility of using the MOSFET channel as

the active region of a Hall plate.

At the same time, the advantage of integrating on the same chip of a magnetic sensor and

the signal processing circuit is outlined.

The Hall devices in MOS structure have some drawbacks: the carrier mobility in the channel

is half of its value in the volume of the device; the increasing of 1/f noise, and the instability of device surface.

The analysis made in this paper outlines the way in which the way of choosing the adequate

choice device material and dimensions allows the improvement of CMOS technology sensors.

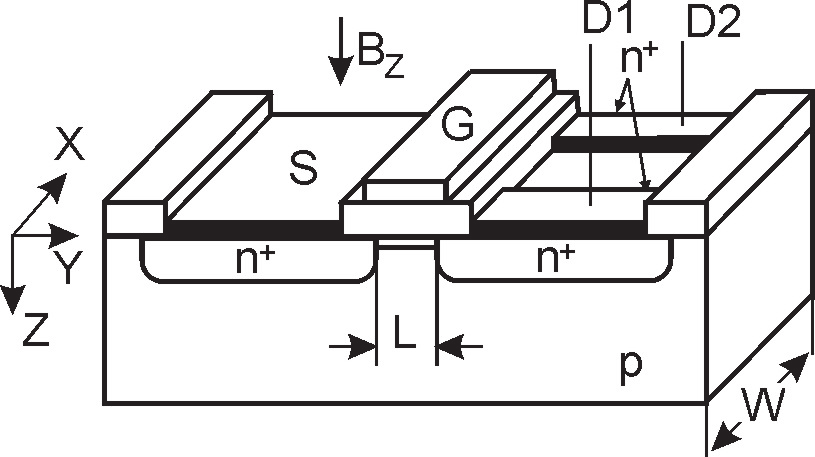

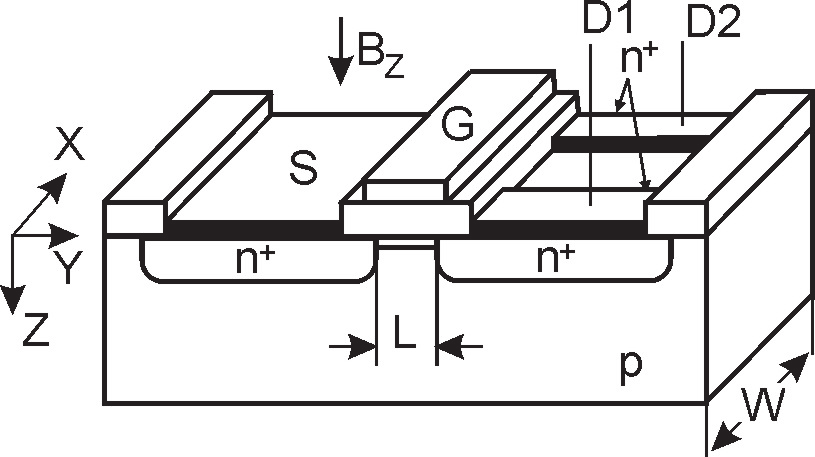

The double-drain magnetotransistor

2.1 The characterisation of the double-drain magnetotransistor

The double – drain MOS device (figure 2.1) is obtained from a MOSFET structure where its

conventional drain region is replaced by two adjacent drain regions[7]. Consequently, the

total channel current is shared between these two drain regions.

Fig. 2.1. Double-drain MOSFET magnetotransistor

The result of the bias is the linear region is the obtained of a continuous channel of

approximately constant thickness, which can be assimilated with a Hall plate.

The deflection of current lines appears under the action of a magnetic field B, perpendicular

to the device surface. The carrier deflection causes a discrepancy between two drain currents:

20

Microsensors

I I ( B) I (0) I ( B) I

(2.1)

D

D

D

D

D (0)

1

1

2

2

Since the output signal of the double-drain MOS magnetotransistors consists of the current

variation between its terminals, this device operates in the Hall current mode. Using the

features of dual Hall devices, and the Hall current expression it results [2]:

I

L

H

1

I

G I B

(2.2)

D

2

2 H

D

Ch W

The supply-current-related sensitivity of the devices is defined by:

1

I

L

D

1

S

G

(2.3)

I

I

B

2 HCh W

D

where G denotes the geometrical correction factor and

is the Hall mobility of the

HCh

carriers in the channel.

For a given induction B 0,4 T and at given drain current I mA , the sensitivity D

1

depends of the device geometry and the material properties.

In table 2.1 the values for five magnetotransistors structures are presented.

Device

W L

2

sm

S [ 1

T ]

C

H

I

MGT1 2 0,07

Si

0,018

MGT2 1 0,07

Si

0,025

MGT3 0,5 0,07

Si

0,028

MGT4 0,5 0,23

InP

0,084

MGT5 0,5 0,42

GaAs

0,146

Table 2.1. The numerical values of the supply-current sensitivity

2.2 The sensor response

The sensor response is expressed by:

I

L