ELECTRIC MACHINES

AND DRIVES

Edited by Miroslav Chomat

Electric Machines and Drives

Edited by Miroslav Chomat

Published by InTech

Janeza Trdine 9, 51000 Rijeka, Croatia

Copyright © 2011 InTech

All chapters are Open Access articles distributed under the Creative Commons

Non Commercial Share Alike Attribution 3.0 license, which permits to copy,

distribute, transmit, and adapt the work in any medium, so long as the original

work is properly cited. After this work has been published by InTech, authors

have the right to republish it, in whole or part, in any publication of which they

are the author, and to make other personal use of the work. Any republication,

referencing or personal use of the work must explicitly identify the original source.

Statements and opinions expressed in the chapters are these of the individual contributors

and not necessarily those of the editors or publisher. No responsibility is accepted

for the accuracy of information contained in the published articles. The publisher

assumes no responsibility for any damage or injury to persons or property arising out

of the use of any materials, instructions, methods or ideas contained in the book.

Publishing Process Manager Katarina Lovrecic

Technical Editor Teodora Smiljanic

Cover Designer Martina Sirotic

Image Copyright demarcomedia, 2010. Used under license from Shutterstock.com

First published February, 2011

Printed in India

A free online edition of this book is available at www.intechopen.com

Additional hard copies can be obtained from orders@intechweb.org

Electric Machines and Drives, Edited by Miroslav Chomat

p. cm.

ISBN 978-953-307-548-8

free online editions of InTech

Books and Journals can be found at

www.intechopen.com

Contents

Preface IX

Chapter 1

Premium Efficiency Motors 1

M. Benhaddadi, G. Olivier, R. Ibtiouen, J. Yelle, and J-F Tremblay

Chapter 2

Electric Motor Performance Improvement Using

Auxiliary Windings and Capacitance Injection 25

Nicolae D.V

Chapter 3

Magnetic Reluctance Method for Dynamical

Modeling of Squirrel Cage Induction Machines 41

Jalal Nazarzadeh and Vahid Naeini

Chapter 4

Minimization of Losses in Converter-Fed

Induction Motors – Optimal Flux Solution 61

Waldiberto de Lima Pires, Hugo Gustavo Gomez Mello,

Sebastião Lauro Nau and Alexandre Postól Sobrinho

Chapter 5

Sensorless Vector Control of Induction Motor Drive

- A Model Based Approach 77

Jogendra Singh Thongam and Rachid Beguenane

Chapter 6

Feedback Linearization of Speed-Sensorless

Induction Motor Control with Torque Compensation 97

Cristiane Cauduro Gastaldini, Rodrigo Zelir Azzolin,

Rodrigo Padilha Vieira and Hilton Abílio Gründling

Chapter 7

From Dynamic Modeling to Experimentation

of Induction Motor Powered by Doubly-Fed

Induction Generator by Passivity-Based Control 113

M. Becherif, A. Bensadeq, E. Mendes,

A. Henni, P. Lefley and M.Y Ayad

Chapter 8

A RMRAC Parameter Identification

Algorithm Applied to Induction Machines 145

Rodrigo Z. Azzolin, Cristiane C. Gastaldini,

Rodrigo P. Vieira and Hilton A. Gründling

VI

Contents

Chapter 9

Swarm Intelligence Based Controller for Electric

Machines and Hybrid Electric Vehicles Applications 161

Omar Hegazy, Amr Amin, and Joeri Van Mierlo

Chapter 10

Operation of Active Front-End Rectifier

in Electric Drive under Unbalanced Voltage Supply 195

Miroslav Chomat

Chapter 11

Space Vector PWM-DTC Strategy

for Single-Phase Induction Motor Control 217

Ademir Nied, José de Oliveira, Rafael de Farias Campos,

Seleme Isaac Seleme Jr. and Luiz Carlos de Souza Marques

Chapter 12

The Space Vector Modulation PWM Control

Methods Applied on Four Leg Inverters 233

Kouzou A, Mahmoudi M.O and Boucherit M.S

Preface

This book focuses on a very important and diverse fi eld of electric machines and

drives. The history of the electric machine, which is the keystone of electromechanical

energy conversion, dates back to the beginning of the nineteenth century. The names

of famous scientists, such as Michael Faraday, Joseph Henry or Nikola Tesla, are associ-

ated with the invention of the rotating electric machine. Electric drives have quickly

become an integral part of our everyday lives and we can hardly imagine our civiliza-

tion without them. Electric drives play a vital part in industry, transportation as well as

in modern households. If we counted the number of electric drives around every one of

us today, we would certainly be surprised how big the number is.

Since the invention of the fi rst electric machine, novel principles and designs have been

appearing and the properties and parameters of electric machines have been steadily

improving. The advent of power electronics and modern control circuitry at the end

of the twentieth century caused a revolution in the fi eld of electric drives. Nowadays,

when modern technologies are available and advanced materials and techniques com-

monly utilized, formerly inconceivable results can be achieved in the fi eld of modern

electric drives.

The twelve chapters of the book writt en by renowned authors, both academics and

practitioners, cover a large part of the fi eld of electric machines and drives. Various

types of electric machines, including three-phase and single-phase induction ma-

chines or doubly fed machines, are addressed. Most of the chapters focus on modern

control methods of induction-machine drives, such as vector and direct torque control.

Among others, the book addresses sensorless control techniques, modulation strate-

gies, parameter identifi cation, artifi cial intelligence, operation under harsh or failure

conditions, and modelling of electric or magnetic quantities in electric machines. Sev-

eral chapters give an insight into the problem of minimizing losses in electric ma-

chines and increasing the overall energy effi

ciency of electric drives, which is currently

viewed as a priority.

I would like to express my gratitude to all the authors for their contributions, in which

they shared their valuable experience and knowledge with the readers. It was their im-

mense involvement that enabled the publication of this book. I would also like to thank

the InTech staff for their great eff ort and support in preparation of the book. I hope it

X

Preface

will benefi t the fi eld of electric machines and drives, provide the readers with a new

point of view on this interesting branch of electrical engineering and possibly initiate

many inventions and innovations in the future.

Miroslav Chomat

Institute of Thermomechanics AS CR, v.v.i.

Czech Republic

1

Premium Efficiency Motors

M. Benhaddadi1, G. Olivier1, R. Ibtiouen2, J. Yelle3, and J-F Tremblay3

1École Polytechnique de Montréal, dépt. de génie électrique, C.P. 6079

Succursale Centre-ville, Montréal, Québec, H3C 3A7

2École Nationale Polytechnique d’Alger, dépt. de génie électrique, Avenue Pasteur

BP 182, El Harrach, 16200 Alger

3Cégep du Vieux Montréal, dépt. Technologie de génie électrique, 255 Ontario-Est

Montréal, Québec, Canada H2X 1X6

1,3Canada

2Algérie

1. Introduction

Despite its considerable potential for energy savings, energy efficiency is still far from

realizing this potential. This is particularly true in the electrical sector (IEA, 2010). Why?

There is no probably just one single answer to this question. A consequential response

requires major multiform research and an analytical effort. No doubt that analysis of the

interaction between energy efficiency policies and energy efficiency performance of

economies accounts for a significant part of the effort.

In the future sustainable energy mix, a key role will be reserved for electricity, as GHG

emissions reduction in this sector has to be drastically reduced. In this option, obvious

conclusion is that large market penetration Premium motors needs a complex approach

with a combination of financial incentives and mandatory legal actions, as industry doesn’t

invest according to least life cycle costs (DOE, 2010).

This present work illustrates the induced enormous energy saving potential, permitted by

using high-efficiency motors. Furthermore, the most important barriers to larger high-

efficiency motors utilization are identified, and some incentives recommendations are given

to overcome identified impediments.

In the present work, experimental comparison of the performance characteristics of 3 hp

Premium efficiency motors from three different manufacturers has been presented. The

motors were tested according to Standard IEEE 112-B.

2. Energy, climate change and electricity

According to last report Intergovernmental Panel on Climate Change IPCC report (IPCC,

2007), the observed increase in global average temperatures since the mid-20th century is

very likely due to the observed increase in anthropogenic greenhouse gas concentrations.

Moreover, there is no doubt that discernible human influences now extend to other aspects

of climate, including ocean warming, continental-average temperatures, temperature

extremes and wind patterns. Stabilizing atmospheric carbon dioxide concentrations at twice

2

Electric Machines and Drives

the level of pre-industrial times is likely to require emissions reductions up to 90 % below

current levels by 2100. Clearly, reductions of this magnitude can be achieved only by taking

action globally and across all sectors of the economy. The electricity sector will undoubtedly

need to assume a major share of the weight, according to its contribution to overall

emissions estimated to be more 10 000 Mt (million tone) CO2eq per year.

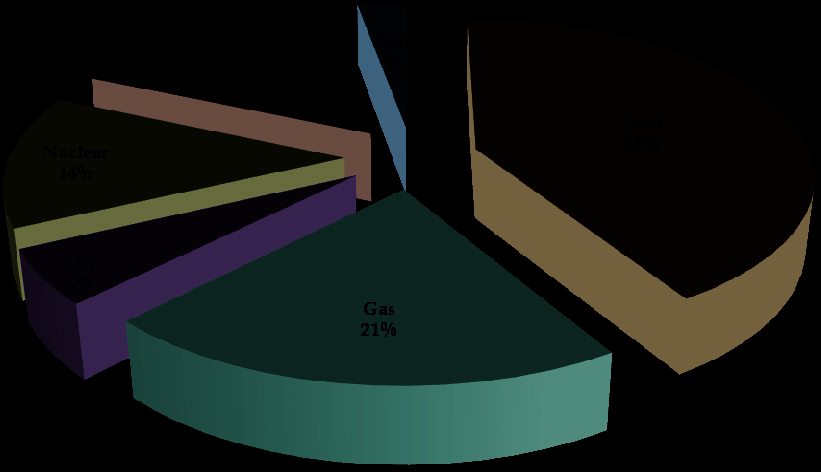

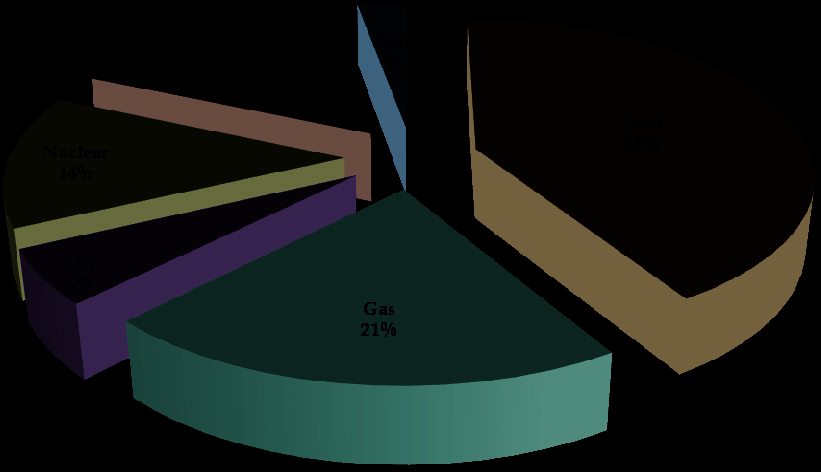

As can be seen in fig.1, the electricity generation is dominantly produced from fossil fuels

(coal, oil, and gas), and today’s situation is the same as forty years ago (DOE, 2010). In the

last XXI world energy congress, it is highlighted that electricity generation will still depend

on fossil sources. In the meantime, according to (IEA, 2010), industry accounts for more 40 %

of the world 20 000 TWh (terawatt hours, or so called billion kilowatt hours) electricity

consumption, weighting more 4 000 Mt CO2eq per year. Within the industrial sector, motor

driven systems account for approximately 60% to 65% of the electricity consumed by North

American (RNC 2004, DOE 2010) and European Union industries. Implementing high

efficiency motor driven systems, or improving existing ones just by 1 to 2 %, could save up

to 100-200 TWh of electricity per year. This would significantly reduce the need for new

power plants. It would also reduce the production of greenhouse gases by more 100 million

CO2eq per year and push down the total environmental cost of electricity generation.

The worldwide electric motors above 1 hp can be estimated to be nowadays more 300

million units, with the annual sales of 34 million pieces. Typically, one-third of the electrical

energy use in the commercial sector and two-thirds of the industrial sector feed the electrical

motors (DOE, 2010). Moreover, the low voltage squirrel cage induction motor constitutes the

industry workhorse. In particular industrial sector such as the Canadian petroleum and

paper industry, the share of the energy used by electrical motors can reach 90% (RNC 2004).

Since induction motors are the largest electrical energy user, even small efficiency

improvements will result in very large energy savings and contribute to reduce greenhouse

gas emissions GHG. Furthermore, the declining resources combined environmental global

warming concerns and with increasing energy prices make energy efficiency an imperative

objective.

Fig. 1. Electricity generation by fuel

Premium Efficiency Motors

3

3. Motor losses segregation and efficiency

The impact of a motor in terms of energy and economical costs depends on its performance

during its lifetime. The motor performances are characterized by the efficiency with which it

converts electrical energy into mechanical energy.

In Standard IEEE 112-B the losses are segregated and the efficiency is estimated by the

following formula:

ΔPstr = Pin – Pout – (ΔPel1 + ΔPel2 + ΔPcore + ΔPmech) (1)

Where the electric input power, Pin, is measured with a power analyser and the output

power, Pout, with a torque meter. The overall precision of efficiency assessment mainly

depends on the torque estimation, and with the improved accuracy of recent power

analysers and torque meters, this method can be considered accurate and reliable.

Motor efficiency is defined as a ratio motor mechanical output power and electrical input

power. Hence in order to have a motor perform better, it is important to reduce its losses.

The major motor losses are resistive losses in the stator and the rotor windings, and

magnetic losses (hysteresis and eddy current losses) in the cores. Other losses include

mechanical (bearing friction and ventilation), and stray load losses. High efficiency motor

losses relative distribution is not so different at low efficiency one’s; it’s more dependent on

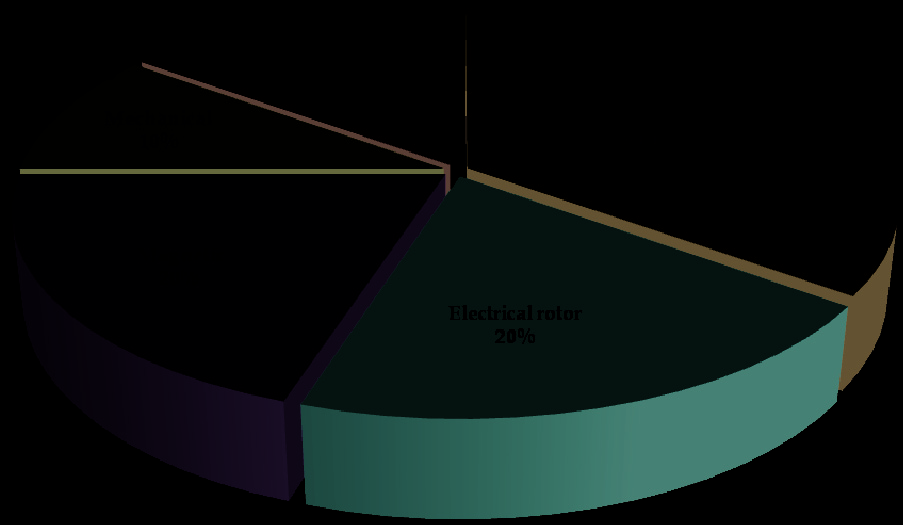

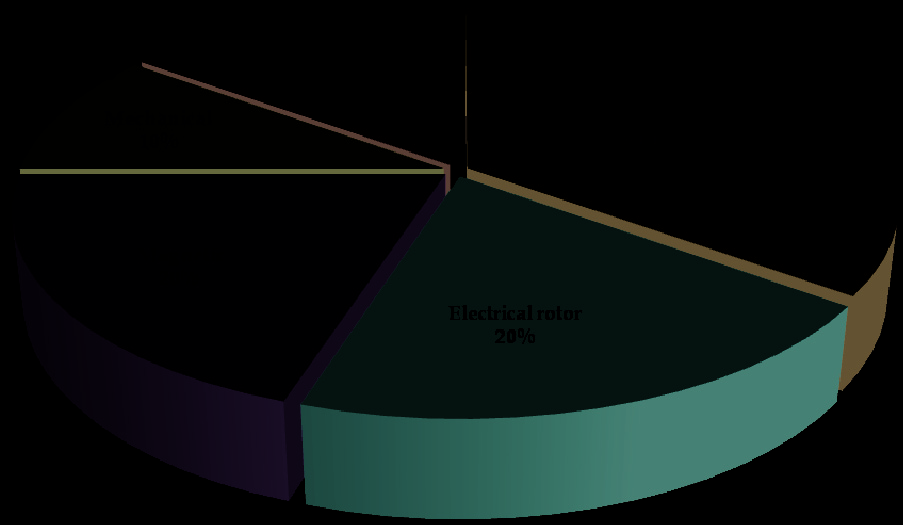

the power. Their general distribution is illustrated in fig.2.

Fig. 2. Induction motor losses distribution

There are many ways to improve electric motor efficiency; the majority of them make the

motor larger in diameter or overall sizes and, of course, more expensive.

•

Winding stator (∆Pel1) and rotor (∆Pel2) losses are due to currents flowing through the

stator windings and rotor bars. These losses can be reduced by decreasing the

conductor current density in the stator windings, in the rotor bars and in the end rings.

Using larger conductors lowers stator resistance, while the use of copper instead of

aluminum reduces rotor losses (Parasiliti et al. 2002). Another way of decreasing stator

losses is by reducing the number of turns. Unfortunately, this increases the starting

current and maximum torque, as worsen the power factor.

4

Electric Machines and Drives

•

Magnetic losses ∆Pm occurring in the stator and rotor laminations are caused by the

hysteresis and eddy current phenomena. These losses can be decreased by using better

grade magnetic steel, thinner laminations and by lowering the flux density (i.e larger

magnetic cores). The better grade of laminations steel are still relatively very expensive.

Cheaper manufacturing methods other than stamping are expected to become available

in the near future.

•

Mechanical losses ∆Pmec are due to bearing friction and cooling fan air resistance.

Improving the fan efficiency, the air flow and using low friction bearings result in a

more efficient design. As these losses are relatively small, the efficiency gain is small

too, but every improvement is welcome.

•

Stray load losses ∆Pst are due to leakage fluxes induced by load current, non-uniform

current distribution, mechanical air-gap imperfection…These losses can be reduced by

design optimisation and manufacturing method improvements.

As can be deducted, one of the most established methods of increasing motor efficiency is to

use higher quality materials, inexorably increasing the motor cost, as most high performance

materials are expensive materials. In a recurrent manner, the same problem of increased cost

holds true for better construction techniques, such as smaller air gaps, copper rather than

aluminum in the rotor construction, higher conductor slot fill, and segmented core stator

construction. The resulting increase in motor cost is evaluated to be between 15 % and 30 %.

4. Testing standards

In North America, the prevailing testing method is based on direct efficiency measurement

method, as described in the Institute of Electrical and Electronics Engineers (IEEE) “Standard

Test Procedure for Polyphase Induction Motors and Generators” IEEE 112-B and in its Canadian CSA 390 adaptation. The standard first introduced in 1984 and updated in 2004, requires the

measurement of the mechanical power output and the electric input, and provide a value for

the motor losses, where the additional stray load losses are extrapolated from their total by

the following formula (1). So, the efficiency is extrapolated by:

Pout

Pout

η

=

=

(2)

Pin

Pout+

Δ

Pel 1+ Δ

Pel 2 +

Δ

Pm +Δ

Pmec + Δ

Pst

In Europe, the prevailing testing method is based on an indirect efficiency measurement as

defined in IEC 34-2 standard “Rotating electrical machines – Part 2: Methods for

determining losses and efficiency of rotating electrical machinery from tests”. The standard

first introduced in 1972 and updated in 1997, attribute a fixed value, equal to o.5 % of input

power to the additional stray load losses.

These standards differ mainly by the method used to take into account the additional load

losses (Aoulkadi & Binder, 2008, Boglietti et al 2004, Nagorny et al. 2004, Elmeida et al.

2002…). Many papers have been published and some authors have illustrated, that IEC 34 –

2 has drawback with a noticeable influence on the testing of high efficiency motors, as the

efficiency of this motor type is overestimated, particularly in the small motor size cases.

Ultimately, standard IEC 34 – 2 was found to be unrealistic with its 0.5 % Pin value for stray

losses (Aoulkadi & Binder, 2008, Renier et al. 1999, Boglietti et al 2004…). That is why, in

2007, IEC published a revised standard for efficiency classification no. 60034-2-1 which

includes a test procedure largely comparable to IEEE 112-B or CSA C390. Newly

Premium Efficiency Motors

5

harmonized standards for energy efficiency testing IEC 60034-2-1 can contribute to lowering

barriers in global trade for energy efficient motor systems.

5. Minimum energy performance standard MEPS and efficiency motor

classification

There are many different worldwide definitions for energy efficient motors, as until these

last years, there was no consensus on what really represents an energy efficient motor.

Technical barriers include non harmonized testing standards and efficiency classification. In

reality, the key mandatory instrument is minimum energy performance standards (MEPS).

5.1 MEPS in North America

On October 1992, US Congress voted law, Energy Policy Act EPAct, which mandates strict

energy efficiency standards for electrical appliances and equipment, including electric

motors. Motor MEPS were for the first time introduced in 1992 when all partners were

finally persuaded that voluntary measures are too slow, and no significant market

transformation towards more efficient motors was possible otherwise.

EPAct requires that the general purpose electric motors meet the higher nominal efficiency

requirements defined in the table of National manufacturer association NEMA Standard,

and the implementation of the motor MEPS went into effect in 1997.

The Canadian Standard association developed a Canadian standard in 1993, and updated it

in 1998. CAN/CSA C-390 set the requirement for minimum efficiency for new motors made

or sold in Canada at the same value as the NEMA energy-efficient level.

The Energy Policy Act EPAct-92 motors covered are:

•

General purpose

•

Definite or special purpose in a general purpose application

•

Continuous duty

•

2, 4 & 6 Pole

•

1-200 HP

•

230/460/, 60 Hz

The Canadian standard was furthermore extended to 575 V and IEC motors, and included

75 % full load to reach maximum efficiency.

Some motors were not covered:

•

Definite or special purpose in a non-general purpose application

•

Slower speeds

•

Inverter duty

•

Multi-speed

•

Totally enclosed air over TEAO, and totally enclosed not ventilated TENV

As a result of the mandatory standard that was endorsed as part of the EPAct-92, North

America had a motor standard foundation that leads the new century world.

In 2002, NEMA and Consortium for energy efficiency CEE established a voluntary NEMA

Premium level of efficiency, and the manufacturers began the next step in evolution with

the implementation on voluntary basis MEPS NEMA Premium efficiency motors. NEMA

premium efficiency standards (CEE 2007) have remained voluntary for a long period of 10

years. In spite of this, NEMA premium motors have been progressively gaining market

share, as the overall benefits of Premium motors is incommensurable (more reliable, last

6

Electric Machines and Drives

longer, have longer warranties, run more quietly and cooler and produce less waste heat

than their less-efficient counterparts). The trend is particularly well depicted in the work,

illustrated in fig. 3.

The evolution of MEPS based on NEMA Premium is now moving from voluntary basis to

legislated regulation, as the law implementation is awaited for December 2010. So, 1 –200

HP general purpose motors already covered by EPAct will change from NEMA MG-1, Table

12-11 Energy Efficient (Annex 1) to Table 12-12 NEMA Premium efficiencies levels (Annex

2), except for fire pump motors which remain at EPAct-92 level.

Moreover, the proposal expands the scope of enclosed 1-200 Hp motors, as several motor

types not previously covered by EPAct-92 must meet EPAct efficiency levels. The added

motors are:

•

U-frame

•

Desig