MICROSENSORS

Edited by Igor V. Minin and Oleg V. Minin

Microsensors

Edited by Igor V. Minin and Oleg V. Minin

Published by InTech

Janeza Trdine 9, 51000 Rijeka, Croatia

Copyright © 2011 InTech

All chapters are Open Access articles distributed under the Creative Commons

Non Commercial Share Alike Attribution 3.0 license, which permits to copy,

distribute, transmit, and adapt the work in any medium, so long as the original

work is properly cited. After this work has been published by InTech, authors

have the right to republish it, in whole or part, in any publication of which they

are the author, and to make other personal use of the work. Any republication,

referencing or personal use of the work must explicitly identify the original source.

Statements and opinions expressed in the chapters are these of the individual contributors

and not necessarily those of the editors or publisher. No responsibility is accepted

for the accuracy of information contained in the published articles. The publisher

assumes no responsibility for any damage or injury to persons or property arising out

of the use of any materials, instructions, methods or ideas contained in the book.

Publishing Process Manager Sandra Bakic

Technical Editor Teodora Smiljanic

Cover Designer Martina Sirotic

Image Copyright JOANCHANG, 2010. Used under license from Shutterstock.com

First published May, 2011

Printed in India

A free online edition of this book is available at www.intechopen.com

Additional hard copies can be obtained from orders@intechweb.org

Microsensors, Edited by Igor V. Minin and Oleg V. Minin

p. cm.

ISBN 978-953-307-170-1

free online editions of InTech

Books and Journals can be found at

www.intechopen.com

Contents

Preface IX

Part 1 Magnetic Sensors 1

Chapter 1

Magnetic Microsensors 3

Căruntu George and Panait Cornel

Chapter 2

Photoelectronic Magnetic Microsensor

with a Digit Readout 49

Hsing-Cheng Chang

Chapter 3

Development of Resonant Magnetic

Field Microsensors: Challenges

and Future Applications 65

Agustín L. Herrera-May, Luz A. Aguilera-Cortés,

Pedro J. García-Ramírez, Nelly B. Mota-Carrillo,

Wendy Y. Padrón-Hernández and Eduard Figueras

Part 2 Chemical Microsensors 85

Chapter 4

A Heat Flux Microsensor

for Direct Measurements

in Plasma Surface Interactions 87

Dussart Rémi, Thomann Anne-Lise

and Semmar Nadjib

Chapter 5

Microsensors for Microreaction and

Lab-on-a-chip Applications 109

Pawel Knapkiewicz and Rafal Walczak

Chapter 6

Chemical Microsensors

with Ordered Nanostructures 143

Marina Vorozhtsova, Jana Drbohlavova

and Jaromir Hubalek

VI Contents

Part 3 Optical Microsensors 159

Chapter 7

Surface-Enhanced Raman Scattering Sensors

based on Hybrid Nanoparticles 161

Rafael Contreras-Cáceres, Benjamín Sierra-Martín and

Antonio Fernández-Barbero

Chapter 8

Optical Fiber Microsensor of Semidrop 185

Esteban Molina-Flores, R. B. López-Flores, Daniel Molina-Flores,

José A. Dávila-Píntle, Germán A. Muñoz-Hernández

Carlos A. Gracios-Marín and Enrique Morales-Rodríguez

Chapter 9

A Glass Capillary-based Microsensor for L-Glutamate

in in vitro Uses 203

Masao Sugawara and Atushi Shoji

Chapter 10

Diffractive Optics Microsensors 217

Igor V. Minin and Oleg V. Minin

Part 4 Microsensors Application 235

Chapter 11

Strength Reliability of Micro

Polycrystalline Silicon Structure 237

Shigeru Hamada, Kenji Hasizume,

Hiroyuki Nakaura and Yoshihide Sugimoto

Chapter 12

MEMS Gyroscopes for Consumers and

Industrial Applications 253

Riccardo Antonello and Roberto Oboe

Chapter 13

Planar Oxygen Sensors for Non Invasive

Imaging in Experimental Biology 281

Henning Tschiersch, Gregor Liebsch, Achim Stangelmayer,

Ljudmilla Borisjuk and Hardy Rolletschek

Preface

Microsensors are appropriately categorized as “transducers”, which are defined as de-

vices that convert energy from one form to another. In the case of microsensors, the

device typically converts a measured mechanical signal into an electrical signal. The

critical physical dimensions of microsensors devices can vary from well below one mi-

cron on the lower end of the dimensional spectrum, all the way to several millimeters.

Sensors and microsensors are: force and pressure microsensors, position and speed

microsensors, acceleration microsensors, chemical microsensors, biosensors and tem-

perature sensors.

The common trends in sensor technology today are: Miniaturization, Integration: sen-

sor with signal processing circuits for linearising sensor output, etc., sensor with built-

in actuator for automatic calibration, change of sensitivity etc., and Sensor arrays: one-

function units (to improve reliability), multiple-function units.

The main advantages of microsensors, as it is well-known, are: lower manufacturing

cost (mass-production, less materials), wider exploitation of IC technology (integra-

tion), wider applicability to sensor arrays, lower weight (greater portability).

Over the last years, advances in microsensors, computing, physics, chemistry, have

enabled new and innovative tests that have allow to design a new devices to improve

outcomes.

This book is planned to publish with an objective to provide a state-of-art reference

book in the area of microsensors for engineers, scientists, applied physicists and post-

graduate students. Also the aim of the book is the continuous and timely dissemina-

tion of new and innovative research and developments in microsensors.

This reference book is a collection of 13 chapters characterized in 4 parts: magnetic

sensors, chemical, optical microsensors and applications.

This book provides an overview of resonant magnetic field microsensors based on

MEMS, optical microsensors, the main design and fabrication problems of miniature

sensors of physical, chemical and biochemical microsensors, chemical microsensors

X Preface

with ordered nanostructures, surface-enhanced Raman scattering microsensors based

on hybrid nanoparticles, etc.

Several interesting applications area are also discusses in the book like MEMS gyro-

scopes for consumer and industrial applications, microsensors for non invasive imag-

ing in experimental biology, a heat flux microsensor for direct measurements in plas-

ma surface interactions and so on.

Igor V. Minin and Oleg V. Minin

Novosibirsk State Technical University,

Russia

Part 1

Magnetic Sensors

1

Magnetic Microsensors

Căruntu George and Panait Cornel

Faculty of Electronics, Electrotechnics and Computer Science,

Constanta Maritime University,Constanta,

Romania

1. Introduction

In the presence of a magnetic field, the Hall effect takes place in the active region of the

transistors, however their magnetic sensitivity is insignificant.Moreover, the Hall effect may

interfere with the action of a bipolar transistor in many ways which makes the analysis and

optimization of devices much more difficult.

However, there are also magnetotransistors structures in which, under appropriate

operating conditions the magnetic sensitivity increases to values useful in practical work. In

this way integrated magnetic sensors useful for emphasizing and measuring mechanical and

geometrical quantities can be obtained.

The double-collector bipolar magnetotransistors

1.1 The general characterization of the double-collector bipolar magnetotransistors

Figure 1.1 shows the cross section of a double collector npn vertical magnetotransistor

operating on the current deflection principle [1]. This structure is compatible with the

bipolar integrated circuit technology.

Fig. 1.1. The structure of a double-collector magnetotransistor

The most of the n type low-doped epitaxial layer serves as the collector region and is

depleted of the charge carriers upon reverse biasing of the collector-base junction. The two

collector contacts are realised by splitting the buried layer ( n ) . L is the collector-emitter distance, and W is the width of the emitter. In the absence of the magnetic field the

E

electron flow injected into the emitter, which crosses the base is symmetrical and the two

collector currents are equal: I I . In the presence of a magnetic field having the

C 1

C 2

4

Microsensors

induction B parallel with the device surface, the distribution of the emitter electron current becomes asymmetrical and causes an imbalance of the collector currents: I I I .

C

C 1

C 2

The analysed magnetotransistor operates in the Hall current mode and I depends on the

C

Hall transverse current. Assimilating the low-dopped epitaxial layer of the collector region

with a short Hall plate, and based on the properties of dual Hall devices it results [2]:

I

L

H

1

I

G I B

(1.1)

C

2

2 Hn

C

WE

where

is the carriers Hall mobility in the channel, G denotes the geometrical correction

HCh

factor and I I

I

.

C

C 0

C 0

1

2

1.2 The sensor response and the sensitivity related to the bias current

The sensor response is expressed by:

I

L

C

1

(

h B)

G B

(1.2)

( I I

W

C ) B

2 Hn

C 1

2

0

E

and it is linear for induction values which satisfy the condition: 2

2

B

H

1

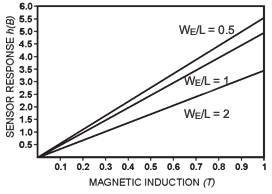

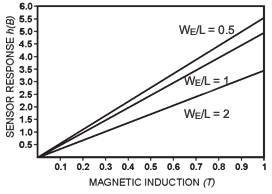

Fig. 1.2. The h(B) depending on B for three devices of different geometry

In figure 1.2 the geometry influence on hBvalues for three magnetotransistor structures

can be seen ratios W

L W

m .

E

50

E /

MGT1: W

L

, L / W G

E

0.72;

E /

0.5

MGT2: W

L , L / W G

E

0.68;

E /

1

MGT3: W

L , L / W G

E

0.46;

E /

2

Magnetic Microsensors

5

It is noticed that the response h B is maximum for W

L

structure.

Decreasing

E /

0.5

the emitter-collector distance, h B decreases with 37.5% for W L , as compared to the E

2

maximum value. The sensor response decreases with 10.7%, comparative with W

L

E /

0.5

structure if the distance between emitter and collector doubles. For the same geometry

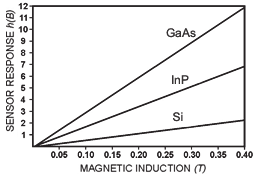

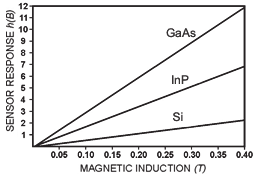

W

L

, the response is depending on material features. In figure 1.3 h B values of

E /

0.5

three sensors MGT1, MGT2, MGT3 are shown, realized on

Si (

2

1

1

0.15 m V s

),

Hn

InP (

2

1

1

0.46 m V s

)

Hn

GaAs (

2

1

1

0.80 m V s

).

Hn

Fig. 1.3. The h(B) depending on B for three devices on different materials

A magnetotransistor may be regarded as a modulation transducer that converts the

magnetic induction signal into an electric current signal.

This current signal or output signal is the variation of collector current, caused by

induction B .

The absolute sensitivity of a magnetotransistor used as magnetic sensors is:

1

L

S I

B

G I

(1.3)

A

C /

2 Hn

C

WE

The magnetic sensitivity related to the devices current is defined as follows:

1

I

L

C

1

S

G

(1.4)

I

I B

2 Hn W

C

E

For a given induction B 0,4 T and at given collector current I mA , the sensitivity C

1

depends on the device geometry and the material properties. In table 1.1 the obtained values

for five magnetotransistors structures are presented.

6

Microsensors

The analysis of the main characteristics of the double-collector magnetotransistor shows that

the W

L

structure is theoretically favourable to high performance regarding signal-

E /

0.5

to-noise ratio, as well as the offset equivalent magnetic induction. Also substituting the

silicon technology by using other materials such as GaAs or InSb with high carriers mobility

values assure higher characteristics of the sensors

W

L

2

1

1

m V s

1

S T

I [

]

Hn [

]

E /

MGT1 2

0,15

Si

0,035

MGT2 1

0,15

Si

0,05

MGT3 0,5

0,15

Si

0,055

MGT4 0,5

0,46

InP

0,168

MGT5 0,5

0,85

GaAs

0,292

Table 1.1. The numerical values of the supply-current-related sensitivity.

1.3 The offset equivalent magnetic induction

The difference between the two collector currents in the absence of the magnetic field is the

offset collector current:

I

I

I

(1.5)

C

C (0)

C (0)

1

2

off

The causes consist of imperfections specific to the manufacturing process: the contact non-

linearity, the non-uniformity of the thickness and of the epitaxial layer doping, the presence

of some mechanical stresses combined with the piezo-resistive effect.

To describe the error due to the offset the magnetic induction is determined, which

produces the imbalance I

I

. The offset equivalent magnetic induction is expressed

C

C off

by considering the relation (4):

1

I

I

Coff

2

L

Coff

B

G

(1.6)

off

S I

I

W

I C

Hn

C

E

Consid